Other complex working condition

Other complex working condition

Xinhui valve is easy to apply to the harsh working conditions of the valve and Other complex working conditions! If you have requirements on valve working conditions, you can consult us, we can customize the best valve for your industry!

-

Butterfly valves

Best Worm Gear Telescopic Butterfly Valve manufacturer

-

Butterfly valves

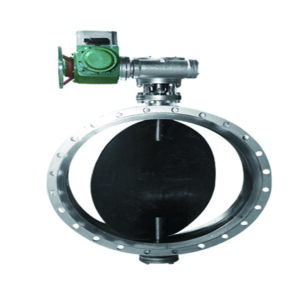

API GB Electric flange type ventilation butterfly valve

-

Control valves

Best Pneumatic sealing single seat bellows control valve

-

Control valves

API factory Lever Type Direct Action Pressure control Valves

-

Check valves

H42F4(F46) Fluorine lined check valve

-

Check valves

H41H Lift Check Valve

-

Check valves

H14W Internal Thread Swing Check Valve

-

Check valves

BH664H Exhaust Check Valve

why choose newinteg valve !

Our wish is to get you here without having to look for anyone else!

Full range of valve types

We have hundreds of industrial valves for you to choose from!

Novel valve type

Every year research and development of novel valves are put into production!

Customized valve types

Fully customized valve according to customer needs!

Further complex and widespread working conditions

Let’s briefly analyze other valve types within the 10 common working conditions.

Special valve for refinery hydrocracking and coking unit

Coke ovens are the plants in which coke is produced, an artificial solid fuel obtained from hard coal and used mainly in the metallurgical industry. The production process, called coking or coking, is based on the thermal decomposition of coal by heating to over 1,000 ° C in the absence of air (pyrolysis or dry distillation): in these conditions a combustible gas (called coke gas) and a residue are formed. solid, coke in fact.

Hydrogenating cracking, or cracking in the presence of hydrogen, or hydrocracking, (HCC) is a variant of catalytic cracking, usually carried out at medium-high pressures and temperatures (of the order of 10 MPa and 300 ° C) in the presence of hydrogen.

Since the hydrocracking unit works at high temperature and high pressure, the medium is flammable and explosive hydrogen and hydrocarbons, and the working conditions are special, so the sealing must be reliable.

Therefore, higher demands are placed on both the design and construction of the valve.

In these cases, domestic stainless steel wedge gate valves and CC globe valves are widely used.

Oil and gas special valve

These valves, created to control the flow of oil and gas, have the following basic properties: tightness, compressive strength, safety, adjustability, fluid flow and switching flexibility. If the media are high pressure oil and gas, which are flammable and explosive, the following considerations should be kept in mind based on the various working conditions of the valves:

- In wet natural gas containing hydrogen sulphide and carbon dioxide, special requirements are placed on the valve body material

- If there are residual acid and other corrosive media in the wellhead device and the collection and transport system, it is necessary to select the valve body materials that are anti-corrosive.

- Dust and solid particles accelerate erosion and wear of valve closing parts, therefore it must be considered that the holding torque breaks quickly.

- Outdoors on plateaus, deserts and alpine regions the low temperature makes the valve materials brittle and more exposed to deformations of various kinds.

- Special oil and gas valves used in long distance transportation pipelines require the same pipeline life as they will not be replaced for decades.

Special oil and gas valves are different from ordinary valves because they offer high reliability in harsh conditions and meet the requirements of high strength and no leakage!

Chlorine-containing working conditions

In these working conditions the choice of valves should refer to the “Dry Chlorine Pipeline System” compiled by the American Chlorine Society. Gaseous chlorine or liquid chlorine is highly corrosive, especially if the contains water, as the HCI (hydrochloric acid) formed by mixing chlorine with water will corrode the valve body and trim. Due to the high thermal expansion coefficient of chlorine, if liquid chlorine is sealed in the valve cavity, the pressure in the valve cavity will rapidly increase. Valves used under these conditions should offer reliable mid-cavity pressure relief functions.

Low temperature and freezing working conditions

Although valves for cryogenic service are based on ASME B16.34 and API standards, they also have other design features to ensure reliable operation in cryogenic service.

Such valves can also incorporate a bonnet extension design that extends the distance of the packing and operating mechanism from cryogenic fluids, thereby allowing the stem packing to operate at a higher temperature and ensuring that the valve operating mechanism does not freeze during service. MISS SP-134 provides some details including the hood extension design.

Condition of hydrofluoric acid

Valves used in hydrofluoric acid service should be limited to valve types that have been demonstrated in service or have been tested to successfully operate this service.

Valves to be preferred are those that do not provide an opportunity for solid matter accumulation. It is essential to remember that the various hydrofluoric acid handling operations must be performed by qualified technicians who rigorously check the valves on the market and, furthermore, the design, material and internal geometry details requirements for these valves are very detailed and strict. . Inspection and testing of these valves should be done more frequently than typical ordinary valves.

Working conditions containing hydrogen

The valves used in this service often have a high casting quality compared to conventional casting supplies as hydrogen is an extremely permeable fluid and valves connected by welding, with nominal pressures greater than or equal to 600 psi, reduce potential sources loss in service. API941 covers the selection and use of materials in the hydrogen service.

Oxygen condition

Valves used in oxygen-containing services must follow the CGA G4.4-2003 standard of the Compressed Gas Association “Oxygen Piping Systems” when applicable. Valves for this service must be completely degreased, cleaned and installed under controlled conditions, and must be properly packaged and sealed, as oils and greases are highly flammable in the presence of oxygen. Guidelines are provided in CGA G4.1 “Cleaning Equipment for Oxygen Service”.

Body and shell materials made of bronze or Monel suitable for oxygen-containing services are often used to prevent sparks and ignition from high-energy mechanical impacts. There are silicone-based greases specially formulated for use in oxygen-containing services as standard hydrocarbon oils should not be used in the presence of oxygen.

Pulsating or unstable flow

Check valves used in pulsating or unstable flows require special attention and are often used in piston compressors.

They can be opened and closed quickly with variations in flow, which can cause hammer blows and damage to the valve.

There are several diverging ideas about the types of valves to be used in pulsating and unstable flows but, generally, butterfly check valves, swashplate check valves and axial flow check valves are recommended.

Acid condition (wet H2S condition)

The use of valve materials under acid-containing conditions must comply with the NACEMR0103 standard which limits:

- the hardness of all steel

- it requires the solubilization of austenitic steels

- prohibits the use of certain materials for pressure parts (including valve stems)

- proposes special requirements for bolted connections, welded valves, etc.

Attention should be paid to user responsibility in NACE MR0103, which states that the user must specify whether bolts are exposed to H2S-containing environments. Unless specified by the user, bolts that are not found inside the valve, such as bonnet connecting bolts, are often subject to product standards and conditions containing sulfur are not included in those standards. Body-to-bonnet bolts do not need to meet

NACE requirements if the material used for the bolts does not directly resist the process fluid.

If it is not possible to exclude or evaporate any sulfur spillage from sulfur-containing oils (such as block valves), the bolted connection must comply with NACE standards.

Viscosity or polymerization conditions

Valves used in viscous or hardening services, such as liquid sulfur or heavy oil, often require vapor tracing or vapor jackets to maintain adequate operating temperatures for valve operation. Particular attention should be paid to check valves because their hysteretic response can cause operational problems.

More Valve related articles

I believe you will not regret your choice

Why choose XinHui valve?

Customized on demand

We very much welcome customers to bring your requirements in the industry, our industrial valve solutions include customized on demand! Use the best materials to produce standard compliant valves, If you need valve customization services, please contact us immediately

Valve quality

Xinhui valve strictly controls the quality of the products in each process; on the other hand, it improves the work quality of the employees; and constantly pursues the high performance and high quality of the products, and is committed to becoming the preferred brand of valve products for the majority of users. .

Professional Services

Our salesman will answer your professional industry questions, product questions, transportation questions, etc. Our service personnel are online 7*12 hours. If you encounter time difference problems, please wait patiently for our reply, and we will reply you as soon as possible The problem.

High and new technology

As a high-tech enterprise in China, we can provide complete valve sample drawings, technical support for valve production process, technical support such as maintenance manuals, and strength calculation books. Frequently Asked Questions about Valve Operation.

R&D innovation

Xinhui Valve has invested a lot of manpower and funds in the innovative research and development of valves, and opened laboratories, inspection rooms, and R&D rooms. 20 kinds of new products are developed every year. Customized industry-specific valves for customers, dozens of products under severe valve conditions.

International Standard

The valves we produce meet various international testing indicators, and all kinds of valves are manufactured and accepted according to relevant domestic standards such as GB and JB, as well as international standards such as ANSI, API, JIS, and BS. DIN. Please contact us for special production standards.

We are not only a manufacturer of valves, but also a disseminator of industry knowledge

OEM & ODM XinHui valve Applications

want to talk

with us?

Leave your details and one of our experts will contact you!