Check valves

Check valve manufacturer

XinHui is a Check valves manufacturer, we supply check valves in cast and forged steel materials. Our valve factory in China specializes in the production of high temperature and high pressure check valves for the power station industry. Also a supplier of double plate wafer check valves, inclined plate check valves and non-shock check valves.

Check valve

-

Check valves

API ASME Swash plate type check valve

-

Check valves

Quick shut Evacuate steam pneumatic check valve

-

Check valves

Single flap piston type check valve factory

-

Check valves

Empty Exhaust Check Valve Factory

-

Check valves

H42F4(F46) Fluorine lined check valve

-

Check valves

H41H Lift Check Valve

-

Check valves

H14W Internal Thread Swing Check Valve

-

Check valves

BH664H Exhaust Check Valve

Check Valve Buyer's Guide

More Check valve related articles

Why choose XinHui check valve?

Advantages of advanced equipment

The importance of advanced equipment exceeds that of skilled craftsmen, and many high-precision production requirements cannot be met by hand. Our check valve manufacturer with favorable price and good quality has continuously introduced a large number of advanced and high-precision production equipment over the years to increase the market share of the valve.

Standardized Process Advantage

Our door began to standardize the management of the production process to ensure that each production process has relevant operating rules, and standardized process management will bring huge benefits to enterprises to reduce costs and increase production capacity. It can also bring benefits to customers

Reliable quality advantage

For customers who use check valve products, neither brand nor publicity can make customers have a strong sense of trust in the company. We are a manufacturer of check valves. In order to generate enough reliance on the praise of customers, we must rely on the excellent quality of our products to obtain them.

We are not only a manufacturer of valves, but also a disseminator of industry knowledge

All You Need to Know About Check valves

01

Introduce

what is a Check valve?

What is a Check valve used for?

02

Introduce

03

Introduce

how does a Check valve work?

How to determine the size of the check valve?

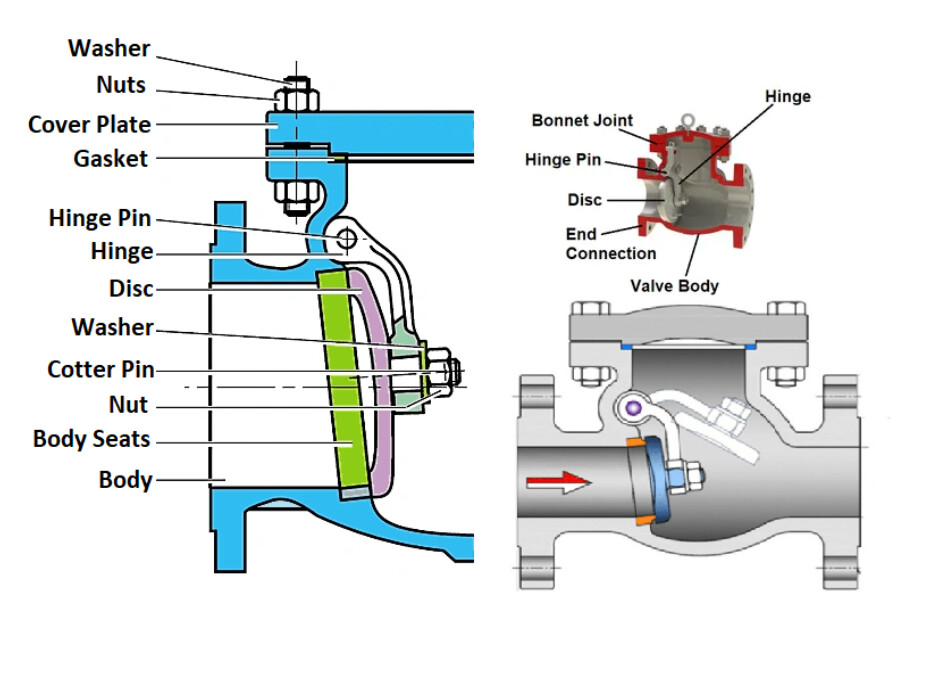

Check valve diagram

This is a schematic diagram of the structure of the swing check valve, which is a one-way valve. When the liquid flows forward, the liquid pushes the valve disc and flows through the swing check valve. When the liquid flows in the reverse direction, the liquid closes the valve, and the liquid cannot pass through the swing check valve.

04

Introduce

05

Introduce

How to Install a Check valve?

Should the check valve be installed before or after the pump?

How far should the check valve be from the pump?

Check valve application scenarios

06

Introduce

OEM & ODM XinHui Check valve Applications

Steam extraction check valve H664Y-recommended for power station industry

For different temperatures, the main material is made of carbon steel or high temperature steel, the sealing surface is surfacing with cemented carbide, and the sealing surface is matched; the sealing surface of the valve seat is inclined at a certain angle to reduce the closing time, reduce the impact, and protect the safety of the equipment itself and the pipeline; equipped with damping The heavy hammer can balance the dynamic moment of the closing part and prevent the occurrence of no hammer; the inner cavity adopts a streamlined design, which has a large flow capacity and reduces the valve resistance;

H41F4 F46 Fluorine lined check valve-recommended for chemical industry

H41F46 fluorine-lined check valve is suitable for various concentrations of aqua regia, sulfuric acid, hydrochloric acid, hydrofluoric acid and various organic acids, strong acids and strong oxidants at -50℃~150℃. FEP is also suitable for various concentrations of strong bases It is used on pipelines of organic solvents and other corrosive gases and liquid media.

H44TC ceramic check valve-recommended power plant industry

H44TC swing type ceramic check valve is used in the inlet and outlet gate of the dry ash system of the power plant, and can also be used in the non-return device of various medium pipelines such as dry ash, water slag, etc. The nominal pressure is 1.0MPa and 1.6MPa, and the suitable temperature is ≤200℃. After the valve is closed, it is completely sealed in any direction. The valve body and bonnet are made of WCB steel castings or stainless steel castings. The sealing surface adopts hard seal. The material port of the valve is fully circulated without obstruction, with strong wear resistance, good sealing performance, small starting load and less ash sticking and ash formation.

H44H swing check valve - recommended for petroleum industry

H44H swing check valve is designed and manufactured in strict accordance with GB12236 standard. The connection between pin shaft and valve disc adopts built-in structure, which has excellent performance and more reliable sealing. The products are widely used in pipelines of various working conditions such as petroleum, chemical, pharmaceutical, and electric power industries.

BH44H insulation check valve-recommended for the pharmaceutical industry

A metal jacket is welded between the flanges at both ends of the BH44H swing-type heat preservation flange check valve. The side and bottom of the check valve are equipped with a jacket connection port for the entry and exit of steam or heat transfer oil, thereby It has the heat preservation effect on the check valve and ensures the normal circulation of viscous medium. Mainly used in the system pipelines of chemical, petroleum, asphalt, pharmaceutical, metallurgy and other industries, the main function is to transport the medium that will solidify and easily crystallize at room temperature.

Strength customers

Testimonials

Check Valves: Ultimate Guide

Types of Check Valves

Swing check valve

Lifting check valve

Disc check valve

Pipeline check valve

Compression check valve

What type of check valve is best?

There is no absolute answer to this, and the one that suits the actual working conditions of different industries is the best!

What causes a check valve to fail?

What causes a check valve to fail?

When should the check valve be replaced?

Most check valves are designed with a welded one-piece seat at the narrow valve throat, usually set at a 30 degree angle. This design makes it nearly impossible to repair the seat surface using “off the shelf” machines and tools. In the past, the lack of equipment that could adequately perform repairs left end users with only one option to restore the integrity of the system—removal and replacement of valves. To reliably remove and replace check valve seats in a cost-effective manner, valve repair suppliers must use custom tools, procedures, and techniques. Using this special tool, craftsmen have successfully replaced the seats of many check valves ranging in size from 12″ NPS to 50″ NPS.

During this repair process, personnel typically:

- Document “as is” condition and dimensions

- Liquid Penetration Testing (LPT) on existing seat surfaces

- Machine removes existing Alloy 21 case hardening

- Carry out LPT of base metal (valve body)

- Base metal repairs if needed

- Install new alloy 21 case hardened

- Machining new seat surfaces to OEM specifications

- Liquid Penetration Testing of New Seat Surfaces

- Reassemble the valve and “blue check” the seat surface to ensure 100% contact

- Document critical valve dimensions “after repair”

These new technologies, along with traditional valve repair procedures, provide the end user with refurbished components that can be returned to OEM specifications in this critical application without the time and expense of a complete valve replacement.

As with all mechanical parts, routine maintenance and inspections are essential to keep these types of valves working properly. Most end users follow a well-planned maintenance schedule; however, it’s worth reviewing the elements of a successful plan:

- Schedule routine inspections and records of valve condition.

- Non-destructive testing of seat surfaces and base metal pressure-bearing components.

- Seat surface condition is maintained through repair processes such as those described herein.

- Refurbish or replace worn valve components found during inspection.

If these types of valves do need to be replaced, please contact the OEM to help select the best valve for the application; allow for rigging and restraint of existing piping before the valve is removed; and take the opportunity to make any configuration changes, to improve the accessibility of valve maintenance.

Do check valves hold pressure?

What comes first check valve or gate valve?

What is the service life of the check valve?

Under normal use, guaranteed repair and maintenance, the service life of the water pipe check valve is 20-40 years!

The service life of check valves has always been a concern of users. The service life of check valves and other products mainly comes from the manufacturing process and raw materials, and partly from the use environment and maintenance.

In the design and manufacturing stage of the check valve, the manufacturer will check the performance of the product and the quality of its own brand as strictly as possible, so as to achieve good results in the design and manufacture of the check valve. Therefore, most of the check valves that can pass the factory qualification inspection stage are guaranteed to reach the normal service life. After the user purchases, the service life will be affected from the time of transportation. During transportation, if the check valve is improperly placed and damaged to a certain extent, the service life will naturally be shortened. Secondly, for the use environment of the check valve, if the use environment is poor and the maintenance is improper, the service life of the check

valve will be shortened accordingly.

The valve body of the check valve is also inevitably contaminated and corroded due to prolonged exposure. For the cleaning of its surface, like other valves, it can be cleaned with the appropriate medium, and after the cleaning is completed, a certain anti-rust oil or anti-fouling coating is applied to it.

Choose manufacturers with quality assurance, like our XinHui Industrial Valve Company. We promise to insist on quality assurance for your valve products!