Valve inspection:Analysis & Testing

Why do valve inspection&tesing?

XinHui valves stand for high quality, reliability and technology.

Quality is an integral part of our company strategy and is visible from the care with which we choose the raw

materials. XinHui’s mission is aimed at continuous improvement by enhancing our staff, motivating them and

stimulating them to learn and update themselves.

all valve

-

pressure reducing valve

Pilot piston type gas pressure reducing valve

-

Ball valves

Cast Steel Swing Type Check Valve manufacturer

-

Check valves

API ASME Swash plate type check valve

-

Check valves

Quick shut Evacuate steam pneumatic check valve

-

Check valves

Single flap piston type check valve factory

-

Check valves

Empty Exhaust Check Valve Factory

-

Control valves

Self-operated pressure full stainless steel control valve

-

Control valves

Pneumatic film Cast Iron Flange three way control valve

You Need to Know About Newinteg Valve Quality Inspection

Valve Metallographic Analysis

Valve Chemical composition analysis

Valve Cryogenic Testing

Valve Hardness Testing

Valve Wall Thickness Testing

Valve Fire testing

Valve life testing

Valve Pressure Testing

valve inspection

Forging inspection(chemical component analysis, tensile impact test,metallographic analysis) incoming quality control(forging and fittings inspection) Process Quality Control(Machining inspection,assembly inspection,stress testing) final inspection(product inspection)

Valve Testing Instruments

- Spectrograph

- High precision Leeb hardness tester

- Impact tester

- Rockwell hardness tester

- Tensile testing machine

- Cryogenic testing chamber

- Ultrasonic thickness gauge

- Helium mass spectrometer

- High temperature test chamber

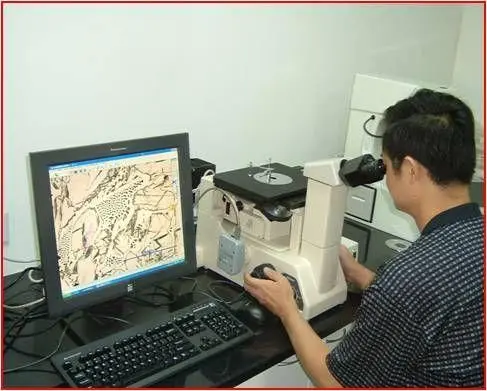

- Microscopic metallographic testing machine

Forging inspection → Incoming inspection → Process inspection → Final test

TA-luft Testing

Pressure Testing

Material Analysis Of Accessories

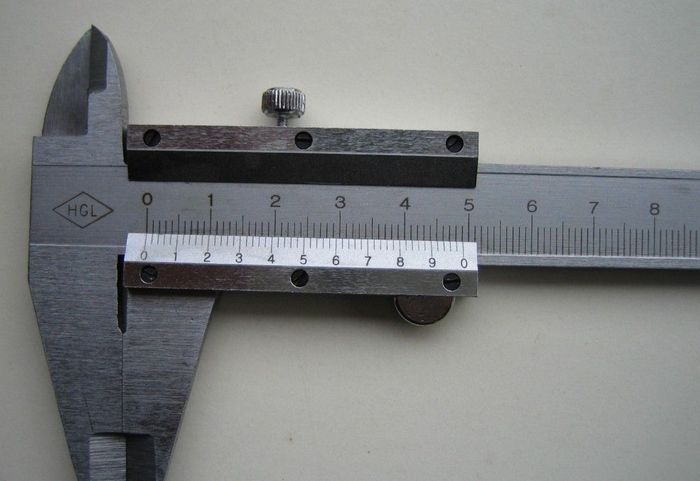

Center Distance Of Valve Body

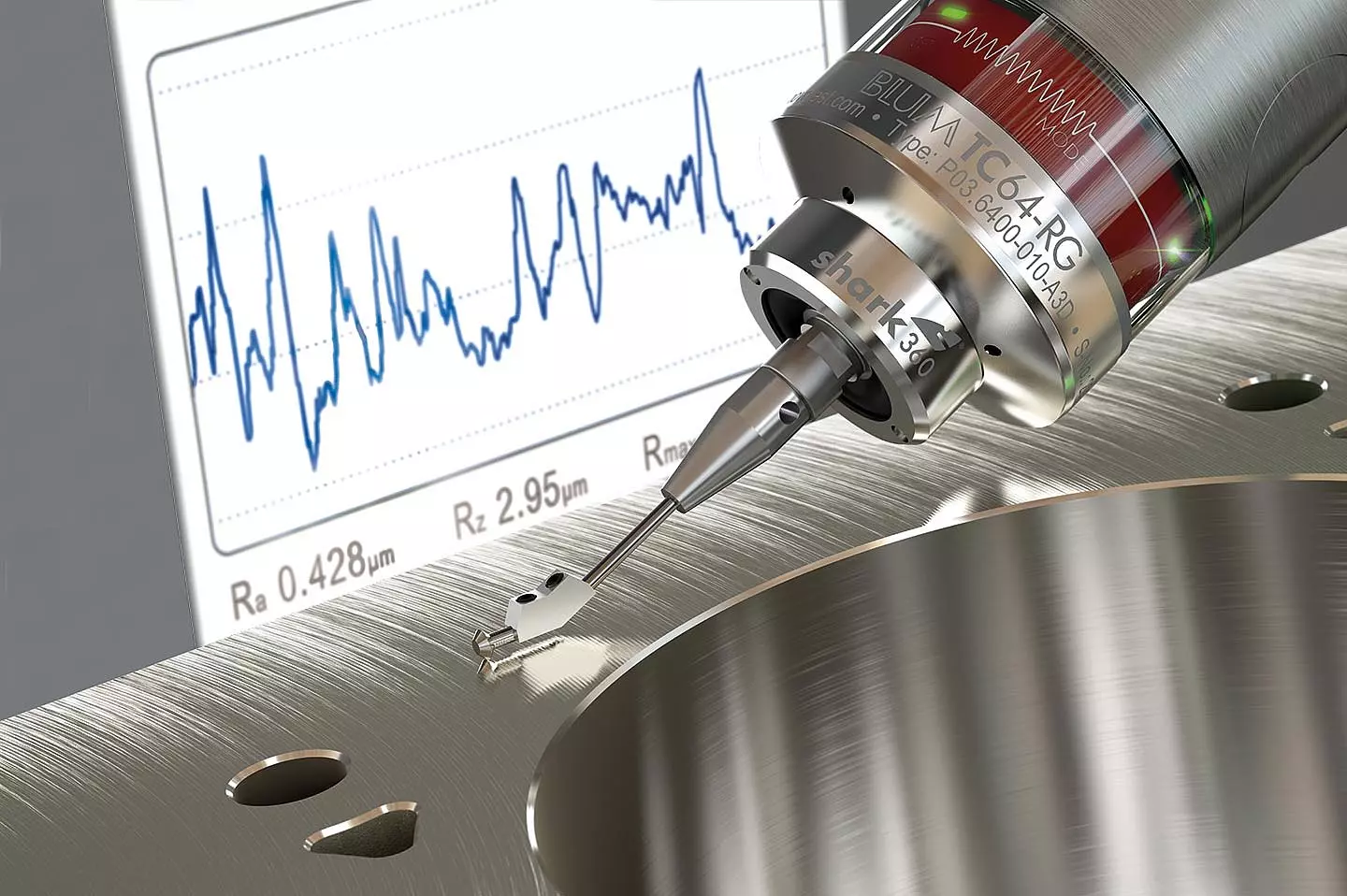

Surface Roughness

Roughness Meter

Measurements

Rockwell Hardness

Material Destructive Testing

Material Inspection

About Me

Valve factory inspection details

valve inspection

Valve inspection and test items

Xinhui Valve Co., Ltd. is a high-tech chemical valve manufacturer integrating R&D, production, sales and service, specializing in the production of power station valves, high temperature and high pressure valves, forged ball valves, three-way ball valves, pigging valves, slurry valves, petrochemical valves Equipment and other products, valve varieties are complete, the first in the industry to pass ISO9001, CE international certification, etc., and put into use in various fields, users highly recognized our company’s valve products.

1. Inspection and test items of various types of valves | |||||||||

Valve class | throttle valve | Diaphragm valve | Plug valve | ||||||

Check and test items | shell body strength | √ | √ | √ | √ | √ | √ | √ | √ |

sealing performance | √ | √ | - | √ | √ | √ | √ | √ | |

Upper sealing performance① | √ | √ | - | - | - | - | - | - | |

quality of castings | √ | √ | √ | √ | √ | √ | √ | √ | |

Continuous trouble-free opening and closing operation | √ | √ | - | √ | √ | √ | √ | - | |

Minimum valve body wall thickness | √ | √ | √ | √ | √ | √ | √ | √ | |

Inner cavity cleanliness | √ | √ | √ | √ | √ | √ | √ | √ | |

Maximum opening and closing torque | √ | √ | - | √ | √ | √ | √ | - | |

Anti-static test | - | - | - | √ | - | - | - | - | |

Fire resistance test ② | - | - | - | √ | - | - | - | - | |

Parts inspection | √ | √ | √ | √ | √ | √ | √ | √ | |

Flow test | √ | √ | √ | √ | √ | √ | √ | √ | |

① Valves with upper sealing performance requirements need to be tested for upper sealing

② Other valves can also be tested for fire resistance if they have fire resistance requirements

2. Inspection and test items of safety valve, pressure reducing valve and steam trap | |||

Valve class | safety valve | pressure reducing valve | Steam Traps Valves |

Inspection and test items | shell body test | shell body test | shell body test |

sealing test | Pressure regulating performance | action performance | |

Set pressure deviation | pressure characteristics | Thermal condensation junction water Displacement | |

discharge pressure | Traffic characteristics | Air leakage volume | |

Turn on height | Continuous trouble-free opening and closing operation | Exhaust Air Capability | |

Mechanics Characteristics | sealing performance | Continuous trouble-free opening and closing operation | |

action repetitiveness | flow | quality of castings | |

Opening and closing pressure difference | quality of castings | highest working pressure | |

Displacement | Inner cavity cleanliness | Minimum working pressure | |

quality of castings | - | Maximum working back pressure | |

Inner cavity cleanliness | - | Maximum subcooling and minimum subcooling | |

- | - | Inner cavity cleanliness | |

- | - | - | |

- | - | Withstand voltage test① | |

①The withstand pressure test is a test of the trap parts that are subjected to external pressure (such as the ball of the floating ball trap, etc.)

3. Factory test and type test items of safety valve, pressure reducing valve and steam trap | ||||||||

safety valve | pressure reducing valve | Steam Traps Valves | ||||||

Test item | out of factory | Type | Test item | out of factory | Type | Test item | out of factory | Type |

shell body strength | √ | √ | shell body strength | √ | √ | shell body strength | √ | √ |

sealing test | √ | √ | sealing test | √ | √ | action performance | √ | √ |

set pressure | √ | √ | Pressure regulating performance | √ | √ | Minimum working pressure | - | √ |

emission pressure | √ | √ | Traffic Features | - | √ | highest working pressure | - | √ |

Opening pressure deviation | - | √ | pressure characteristics | - | √ | Maximum working back pressure | - | √ |

Turn on height | - | √ | flow | - | √ | Exhaust Air Capability | - | √ |

mechanical features | - | √ | Continuous running test | - | √ | Maximum subcooling and minimum subcooling | - | √ |

Displacement | - | √ | - | - | - | Air leakage volume | - | √ |

- | - | - | - | - | - | Thermal condensation junction water Displacement | - | √ |

4. Key items and main items for valve quality grade assessment ①② | ||||||||

Valve class | gate valve | Globe valve | throttle valve | Ball valve | Butterfly valve | Diaphragm valve | Plug valve | check valve |

shell body test | △ | △ | △ | △ | △ | △ | △ | △ |

sealing performance test | △ | △ | - | △ | △ | △ | △ | △ |

Upper sealing test ③ | △ | △ | - | - | - | - | - | - |

quality of castings | △ | △ | △ | △ | △ | △ | △ | △ |

Continuous trouble-free opening and closing operation | △ | △ | - | △ | △ | △ | △ | - |

Minimum valve body wall thickness | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Inner cavity cleanliness | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Maximum opening and closing torque | - | ○④ | - | - | ○ | - | - | - |

gate-Wear-Margin | ○ | - | - | - | - | - | - | - |

Flange dislocation during non-processing | ○ | - | - | - | - | - | - | - |

valve body lining material | - | - | - | - | - | ○⑤ | - | - |

Diaphragm Performance | - | - | - | - | - | ○ | - | - |

①△ is the key item

②○ is the main item

③ Valves with upper sealing performance requirements should be tested for upper sealing

④High pressure balance globe valve has this requirement

⑤Applicable to lined diaphragm valve

5. Key items and main items for quality grade assessment of safety valves, pressure reducing valves and steam traps①② | |||||

safety valve | pressure reducing valve | Steam Traps Valves | |||

shell body test | △ | shell body strength | △ | shell body test | △ |

sealing test | △ | Pressure regulating performance | △ | action performance | △ |

Opening pressure deviation | △ | pressure characteristics | △ | Withstand voltage test④ | △ |

discharge pressure | △ | Traffic Features | △ | Thermal condensation junction water Displacement | △ |

Turn on height | △ | quality of castings | △ | Air leakage volume | △ |

mechanical features | △ | Continuous trouble-free opening and closing operation | △ | Exhaust Air Capability | △ |

action repetitiveness | △ | sealing performance | ○ | quality of castings | △ |

Opening and closing pressure difference | △ | Inner cavity cleanliness | ○ | Continuous trouble-free opening and closing operation | △ |

Spring ③ | △ | - | - | highest working pressure | ○ |

quality of castings | △ | - | - | Minimum working pressure | ○ |

Inner cavity cleanliness | ○ | - | - | Maximum working back pressure | ○ |

Displacement | ○ | - | - | maximum subcooling | ○ |

- | - | - | - | Inner cavity cleanliness | ○ |

- | - | - | - | Pouring-buckle residual amount⑤ | ○ |

- | - | - | - | Residual amount after welding repair⑥ | ○ |

①△ is the key item

②○ is the main item

③Suitable for spring type safety valve

④For trap parts that are subject to external pressure, such as the ball of a floating ball steam trap, etc.

⑤, ⑥ Applicable to mechanical type steam trap with closed float

High temperature valves mainly refer to high temperature valves used in oil refineries. High temperature working conditions mainly include sub-high temperature, high temperature grade I, high temperature grade II, high temperature grade III, high temperature grade IV, and high temperature grade V. See more or contact us for options for various conditions!

More Valve Inspection related articles

Why choose XinHui valve?

Customized on demand

We very much welcome customers to bring your requirements in the industry, our industrial valve solutions include customized on demand! Use the best materials to produce standard compliant valves, If you need valve customization services, please contact us immediately

Valve quality

Xinhui valve strictly controls the quality of the products in each process; on the other hand, it improves the work quality of the employees; and constantly pursues the high performance and high quality of the products, and is committed to becoming the preferred brand of valve products for the majority of users. .

Professional Services

Our salesman will answer your professional industry questions, product questions, transportation questions, etc. Our service personnel are online 7*12 hours. If you encounter time difference problems, please wait patiently for our reply, and we will reply you as soon as possible The problem.

High and new technology

As a high-tech enterprise in China, we can provide complete valve sample drawings, technical support for valve production process, technical support such as maintenance manuals, and strength calculation books. Frequently Asked Questions about Valve Operation.

R&D innovation

Xinhui Valve has invested a lot of manpower and funds in the innovative research and development of valves, and opened laboratories, inspection rooms, and R&D rooms. 20 kinds of new products are developed every year. Customized industry-specific valves for customers, dozens of products under severe valve conditions.

International Standard

The valves we produce meet various international testing indicators, and all kinds of valves are manufactured and accepted according to relevant domestic standards such as GB and JB, as well as international standards such as ANSI, API, JIS, and BS. DIN. Please contact us for special production standards.

We are not only a manufacturer of valves, but also a disseminator of industry knowledge

OEM & ODM XinHui valve Applications

FAQ

Important Types of Valve Inspection and Testing

To give you an idea of what testing is applied to determine the efficacy and the health of valves in industrial applications, we’ll go over those evaluation measures.

Valve Shell Test

The valve is checked for leaks by having it partially open and subject to hydrostatic pressure at 50% higher than the rated working pressure. A specified amount of pressure is applied during this test. There are also specific water temperatures in effect (41°F to 122°F). In order to pass the test, there must not be any leaking from the valve. When valve material includes stainless steel, chloride ion content must be less than 100 ppm.

Valve Seat Leak Test

This test has the valve completely closed with the inlet subject to the hydrostatic pressure with the valve body filled with the testing fluid at a certain temperature.

The outlet side of the valve is monitored for any leaks. Pressure cannot be lower than the 110% maximum allowable pressure at 100 °F. The duration of applied pressure is usually one minute. For the valve to pass the test, it cannot leak from the stem and packing. A minimal amount of leakage from the sealing surface of the disc and seat is acceptable.

Pressure Safety Valve Inspection

This valve inspection observes inlet and outlet piping with pressure safety valve removal.

The following parts are checked for issues of deposit accumulation, corrosion, cracking, pitting, roughness, or other damage:

- External surface

- Discharge nozzle

- Flanges

- Spring and bellows

Backseat Valve Test

For this test, the valve is fully opened while the valve ends are closed. Pressure cannot be lower than the 110% maximum allowable pressure at 100 °F.

The testing duration lasts 15 seconds for a valve that’s less than 2 inches and for valves more than 2 inches, it lasts 60 seconds. During this process, the packing gland is closely inspected while it is under the backseat test pressure. It passes if there are no leaks from the valve or from the packing gland.

The Types of Valve Testing Standards

Below is a breakdown of some of the most common valve testing standards:

API 598: Valve Inspection and Test

API 527: Seat Tightness of Pressure Relief Valves

ASME B16.34: Valves – Flanged, Threaded, and Welding End

ASME PTC 25: Pressure Relief Devices

FCI 70-2: Control Valve Seat Leakage

ISA-S75: Hydrostatic Testing of Control Valves

ISO 5208: Industrial Valves, Pressure Testing of Valves

MSS SP61: Hydrostatic Testing of Steel Valves

MSS SP70: Cast Iron Gate Valves, Flanged, and Threaded Ends

MSS SP71: Cast Iron Swing Check Valves, Flanged, and Threaded Ends

MSS SP78: Cast Iron Plug Valves, Flanged, and Threaded End

MSS SP80: Bronze Gate, Globe, Angle, and Check Valves

MSS SP85: Cast Iron Globe and Angle Valves

All of the above documentation can be gained through a third-party quality management company such as HQTS. Our inspectors are ready to perform testing on your valves to ensure only the best products leave your factory which keeps your customers happy and the environment in a better state.