Butterfly valves

Butterfly valves manufacturer

XinHui is an industrial butterfly valve manufacturer from China. The products of our China Butterfly Valve Factory are: Metal Sealed Butterfly Valves for High Temperature and High Pressure Industrial Use and High Performance Butterfly Valves. We are also a supplier of double eccentric and triple eccentric butterfly valves. The double eccentric type is often used in power stations and the oil industry, while the triple eccentric type can meet the higher requirements of industrial applications.

Butterfly valves

- Butterfly valves

High performance wafer type cut off butterfly valve

- Butterfly valves

Double Seal Vacuum Butterfly Valve supplier in china

- Butterfly valves

Butt welding type triple eccentric hard seal butterfly valve

- Butterfly valves

Best Worm Gear Telescopic Butterfly Valve manufacturer

- Butterfly valves

API GB Electric flange type ventilation butterfly valve

- Butterfly valves

HBD741X(H) Hydraulic Controlled Slow Closing Check Butterfly Valve

- Butterfly valves

D971X Wafer Type Butterfly Valves

- Butterfly valves

D941X Flanged Butterfly Valve

Precautions when buying Butterfly valves

Recommendations for purchasing butterfly valves

Why choose XinHui Butterfly valves?

Cheap

The butterfly valves we produce have competitive prices, which are cheap without cutting corners and materials, strictly in accordance with production standards, especially for large-diameter butterfly valves;

Good adjustment performance

The butterfly valve we produce has good regulation performance, when it is opened, the flow resistance is small, and it has the characteristics of proportional flow control. It can be used for the regulation process control of low pressure and large diameter conditions.

Simple structure

We produce the most practical butterfly valve with the most reasonable design and simple structure. It has the advantages of small size, light weight, saving consumables without sacrificing quality

Strong sealing performance

Through years of efforts, Xinhui Valve has reformed the sealing performance of the butterfly valve, improved the sealing characteristics of the butterfly valve, and the soft-sealed butterfly valve can achieve zero leakage.

Easy to operate

It can be opened or closed only by rotating 90°, so the opening and closing speed is fast and easy to operate. It is worth mentioning that the valves we produce have many opening and closing times and long service life.

Easy maintenance and installation

The valve body has the function of valve seat, and can use the throttling flushing to flush the inner wall of the valve body, which has a "self-cleaning" effect and can be used for unclean media. And the installation space is small and the maintenance is easy.

More Butterfly valves related articles

We are not only a manufacturer of valves, but also a disseminator of industry knowledge

All You Need to Know About Butterfly valves

what is a Butterfly valve

What is a Butterfly valve used for?

how does a Butterfly valve work

Butterfly Valve Structure

How to determine the size of the butterfly valve

How to Install a Butterfly valve

Butterfly valve installation, operation and maintenance guide

Butterfly valve application scenarios

OEM & ODM XinHui Butterfly valve Applications

D341F Fluorine Lined Flanged Butterfly Valve - Recommended for Chemical Industry

As a component used to realize the on-off and flow control of the pipeline system, the fluorine-lined flange butterfly valve is widely used in the petroleum field. Suitable for various concentrations of aqua regia, sulfuric acid, hydrochloric acid, hydrofluoric acid and various organic acids, strong acids, strong oxidants at -50℃~150℃, FEP flange lined fluorine butterfly valve is suitable for various concentrations of strong alkali organic solvents And other corrosive gas, liquid medium pipeline use.

HBD741X(H) Hydraulic Controlled Slow Closing Check Butterfly Valve-Recommended for power station industry

The hydraulically controlled slow-closing check butterfly valve is also a relatively good pipeline control equipment in China. It is mainly installed at the turbine inlet of the hydropower station industry and used as the turbine inlet valve. Therefore, since the hydraulically controlled slow-closing check butterfly valve has been developed, it has replaced the functions of the gate valve and the check valve. Through the preset opening and closing procedures, in this way, the reliable cut-off of the pipeline is realized, the water hammer of the pipeline is effectively eliminated, and the safety of the pipeline system is protected.

D363H Butt Welded Metal Hard Seat Butterfly Valve-Recommended for metallurgical industry

D363H butt welding hard sealing butterfly valve is widely used in metallurgy, electric power, petrochemical industry, water supply and drainage and municipal construction and other industrial pipelines with medium temperature ≤425℃. It adopts precise J-shaped elastic sealing ring and triple eccentric multi-layer metal hard sealing structure, which is used for regulating flow and load-cutting fluid. The valve seat and disc sealing surface are made of different hardness and stainless steel, which have good corrosion resistance. Long life, the valve has bidirectional sealing function

NKD943X double seal vacuum butterfly valve-recommended for chemical and pharmaceutical industries

NKD343X double-sealed vacuum butterfly valve is a new generation of high-tech products successfully developed by our company in combination with new vacuum technology standards at home and abroad.

The valve structure is designed as: double butterfly plate, double sealing seat, three-dimensional eccentric locking structure, cobalt-based hard alloy surfacing on the sealing surface of the valve body, and the sealing ring is made of temperature-resistant, corrosion-resistant rubber and fluorine rubber pressure plate firmly sealed Pressed on the butterfly plate can be removed and replaced for easy maintenance

Top Entry Type Two-way High Pressure Metal Hard Seal Butterfly Valve-Recommended for Petroleum Industry

The top-mounted two-way high-pressure metal hard-sealed butterfly valve has the advantages of simple structure, low cost, convenient maintenance, and does not affect the normal operation of the pipeline system during maintenance.

Strength customers

Testimonials

Butterfly Valves: Ultimate Guide

Why is it called a butterfly valve?

Butterfly valves get their name from the shape and movement of the valve plug. The valve plug is butterfly-shaped, and the valve stem passes through the valve plug, reminiscent of a butterfly. To stop fluid flow, the valve disc rotates 90 degrees on the normal channel where the pipe runs, like butterfly wings.

Is a butterfly valve a control valve?

What are the types of butterfly valves?

Butterfly valves can be divided into segment type and adjustment type according to their use, and can be divided into midline type, single eccentric, double eccentric and triple eccentric butterfly valves according to their structure. .

What is the difference between a ball valve and a butterfly valve?

1- For the first tail the method of shutting off the ball valve and the throttle valve is different as the ball valve blocks the channel through the ball to realize the interruption flow of the pipeline. The butterfly valve relies on the wing of the butterfly and the pipeline will not flow if it is stretched and sealed.

2- The second important difference is that the structure of the ball valve and the valve are not the same. The ball valve consists of the valve body, the valve core and the valve stem, and only some parts are visible in the body. Inevce, the butterfly valve consists of valve body, valve seat, valve plate and valve stem and all accessories are visible. Therefore, it can be seen that the sealing performance of the butterfly valve is not as good as that of the ball valve. Butterfly valves are also divided into soft seals and hard seals. The structure of the butterfly valve is relatively simple, it can only be used in low pressure environment, the maximum pressure is only 64kg. Compared with the ball valve, the ball valve can reach up to about 100 kilograms.

3- The third difference lies in the operating system of the ball valve and the butterfly valve. The ball valve has a 90 degree rotation action, precisely because its opening and closing part is a ball, it can only be opened or closed by operating a 90 degree rotation, which is the most suitable for switching. But now the V-shaped ball valve can be used to regulate or control the flow. The butterfly valve is a type of valve that uses a disc type opening and closing element to oscillate approximately 90 ° to open, close or regulate the flow of fluid. It has a good flow regulating function and is one of the fastest growing valve varieties.

What is the difference between gate valve and butterfly valve?

PRINCIPLE

What are the advantages of a butterfly valve?

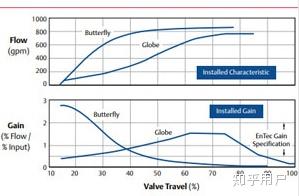

Butterfly valves are lighter, smaller and lighter than other types of control valves and are the best choice for regulating flow in many applications. Traditionally, standard butterfly valves have been used for automatic on/off applications and they are well suited for this role. However, some engineers consider them unacceptable when regulating flow in closed-loop systems.

Limitation of butterfly valve

How to obtain the best control performance

How to improve control

Do butterfly valves need gaskets?

Are butterfly valves suitable for isolation?

How to test butterfly valve?

How much pressure can the butterfly valve withstand?

Are butterfly valves cheaper than ball valves?

Butterfly valves should be the cheapest, followed by ball valves and gate valves, and then globe valves are relatively expensive.