◆Product overview

It is mainly used in the steam extraction system of thermal power generation steam turbines below 600MW to prevent backflow of medium or water, and to protect important facilities such as steam turbine water pumps. The valve can be closed instantaneously under abnormal conditions such as pipeline medium backflow, power failure, and accident, and the closing time is less than 0.5 seconds.

◆Product Features

1. The acceptance standard of design and manufacture adopts ANSIB16.34, E101 or JB/3595. The strength and sealing performance fully meet the requirements of the standard, and the valve under vacuum state is subjected to vacuum test and the life of the whole machine meets user requirements.

2. The valve disc is designed to be movably connected to the valve stem via the rocker, which can be self-aligned with the valve sealing surface to ensure that the sealing surface is consistent.

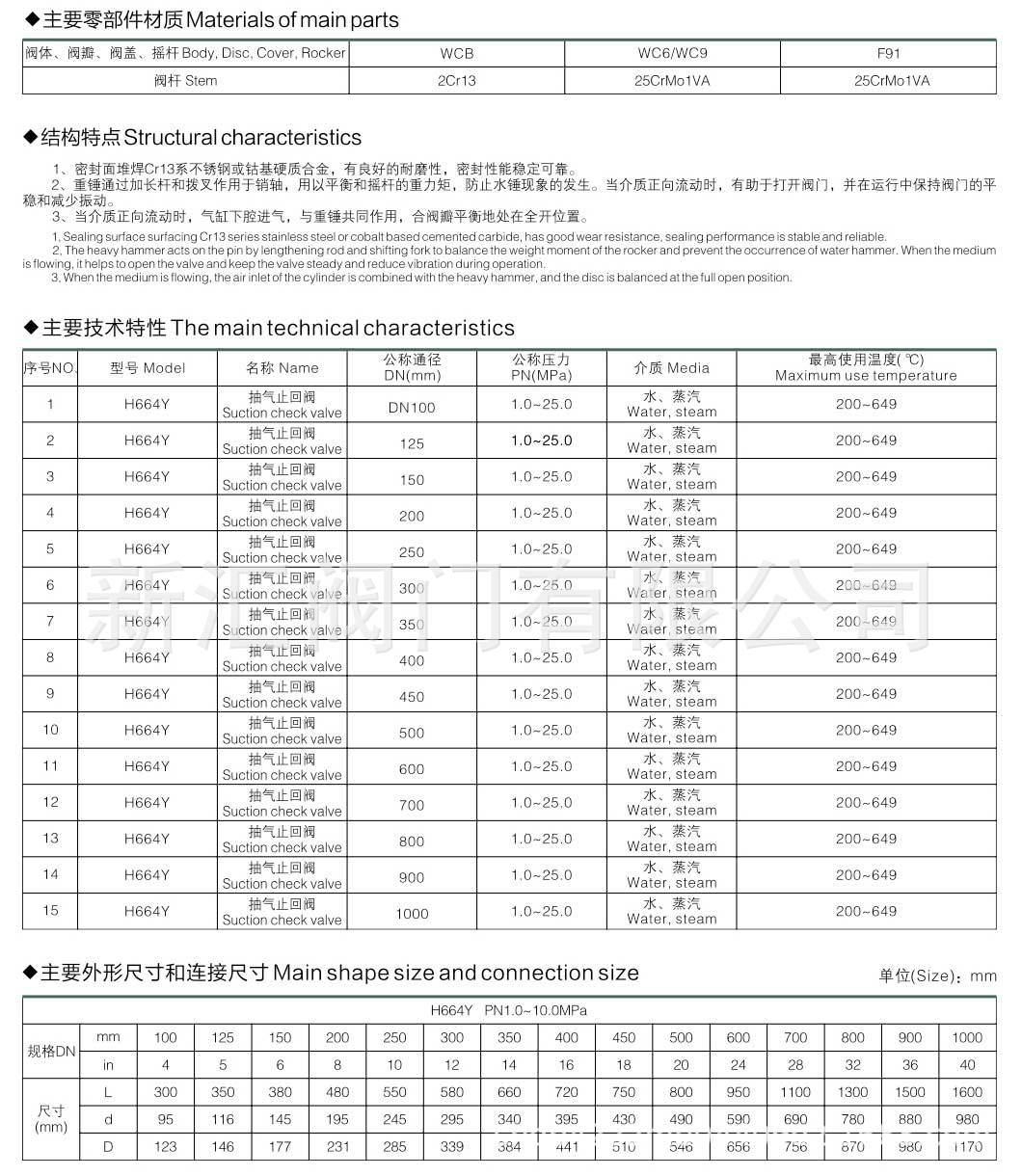

3. For different temperatures, the main material is made of carbon steel or high temperature steel, and the sealing surface is surfacing hard alloy.

4. The valve is equipped with a damping weight, which can balance the dynamic moment of the closing part and prevent the occurrence of water hammer.

5. The sealing surface of the valve seat is inclined at a certain angle to reduce the closing time, reduce the impact, and protect the safety of the equipment itself and the pipeline.

6. The inner cavity of the valve body adopts a streamlined design, which has a large flow capacity and reduces the valve resistance.

7. The actuator is a spring-returned cylinder or hydraulic cylinder, which is relatively independent from the action of the valve closing part, and the failure of the actuator does not affect the action of the closing part.

8. The opening of the closing part is provided with a limit mechanism to avoid damage caused by over-opening.

9. The inner wall of the cylinder or hydraulic cylinder is coated with a wear-resistant and corrosion-resistant layer. It can increase the service life, reduce the negative force of the action, and make the valve flexible and reliable.

10. The actuator is equipped with valve switch position signal output and local indication of valve opening position.

Reviews

There are no reviews yet.