Gate valves

Gate valve manufacturer

Gate valve

-

Gate valves

Forging power station gate valve manufacturer

-

Gate valves

High Temperature Forging Gate Valve manufacturer

-

Gate valves

DZ40Y Cryogenic Gate Valve

Precautions when buying Gate valves

More Gate valve related articles

Why choose XinHui Gate valves?

Wide range of applications

The gate valve has a wide range of applications. Generally, it is used for blocking devices with a diameter of DN ≥ 50mm, and sometimes gate valves are also used for blocking devices with small diameters. The main function of the gate valve is to use it as a cut-off medium. When it is fully opened, it runs smoothly and smoothly, and the pressure loss of the medium is minimal at this time.

Sealing performance

Use conditions or require good sealing performance, high pressure, high pressure cutoff (large pressure difference), low pressure cutoff (small pressure difference), low noise, cavitation and vaporization, high temperature medium, low temperature (cryogenic) It is recommended to use a gate valve. When fully open, the erosion of the sealing surface is small.

Simple structure

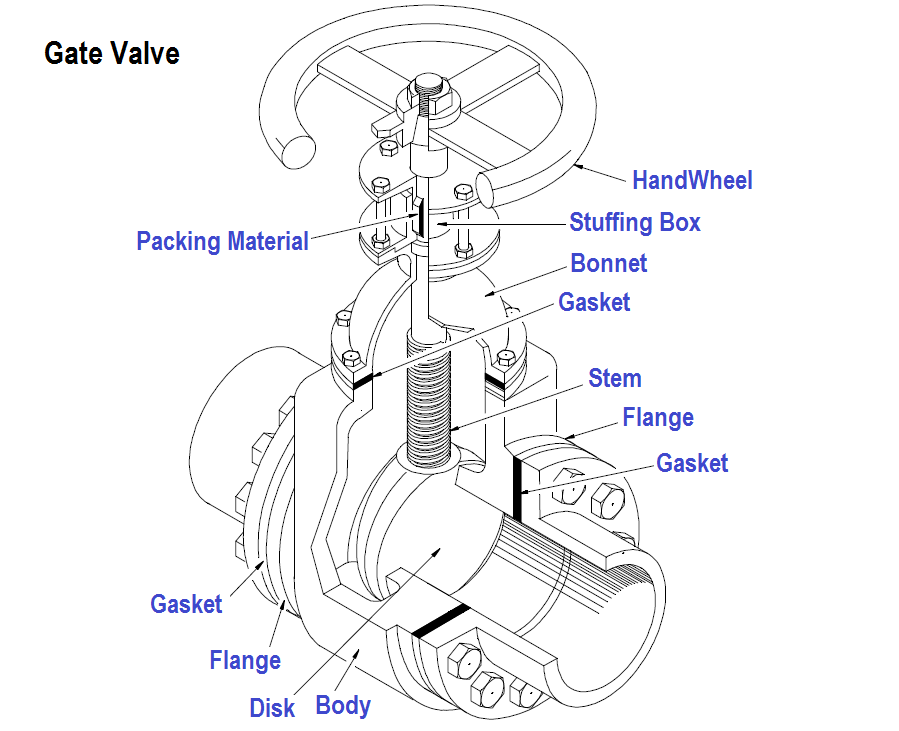

The structure of the gate valve is relatively simple, consisting of a valve body, a valve stem, a gate, a sealing ring and a transmission device. Usually, the transmission device of the gate valve is a hand wheel, only in some special working conditions, it is necessary to use an electric device to operate the gate valve.

low torque

Effortless opening and closing. Due to the opening and closing of the gate valve, the movement direction of the gate valve is perpendicular to the movement direction of the medium. Compared with globe valves, gate valves are less labor-intensive to open and close.

Small fluid resistance

When the valve is fully opened, the medium in the pipeline can pass in a straight line, so the liquid resistance through the valve is small

Easy to install

When the installation space is small, it is suitable for large-diameter valves and pipelines with limited installation space, such as underground pipelines.

We are not only a manufacturer of valves, but also a disseminator of industry knowledge

All You Need to Know About Gate valves

01

Introduce

what is a Gate valve

How to identify a gate valve?

It is easiest to distinguish from the appearance of the valve. The inlet and outlet of the gate valve are on the same straight line, regardless of the installation direction of the inlet and outlet. The valve core is like a gate, and the valve core has parallel plates and wedge-shaped plates to identify the gate valve. In addition, you can check the symbols on the valve body, Z stands for gate valve!

What is a Gate valve used for?

02

Introduce

03

Introduce

how does a Gate valve work

The gate plate moves up and down together with the valve stem. There are trapezoidal threads on the valve stem. The up and down movement of the valve stem is realized through the nut at the top of the valve and the guide groove on the valve body. When the valve stem drives the gate plate to make the pipeline Medium circulation and truncation inside. The movement direction of the gate is perpendicular to the direction of the fluid medium in the pipeline.

Gate valve structure

04

Introduce

05

Introduce

How To Install A Gate Valve

P recautions for gate valve installation

- The valve cavity, sealing surface and other parts must be inspected before installation, and no dirt or sand shall be attached

- It is necessary to evenly tighten the bolts of each connection part

- Check that the packing part is required to be pressed, not only to ensure the sealing of the packing, but also to ensure the flexible opening of the gate

- Before installing the valve, the user must check the valve model and connection size, pay attention to the flow direction of the medium, and ensure that it is consistent with the valve requirements

- The necessary space for valve drive must be reserved by the user when installing the valve

- The wiring of the drive device must be carried out according to the wiring diagram

- In order to ensure the sealing effect of the gate valve, it must be maintained regularly, and it must not be bumped and squeezed at will

How To Install A Gate Valve

Gate valve application scenarios

The gate valve has a wide range of applications. Generally, it is used for blocking devices with a diameter of DN ≥ 50 mm, and sometimes gate valves are also used for blocking devices with small diameters. The main function of the gate valve is to use it as a cut-off medium. When it is fully opened, it runs smoothly and smoothly, and the pressure loss of the medium is minimal at this time. Gate valves are usually used in conditions that do not need to be opened and closed frequently and keep the gate fully open or fully closed.

Not suitable for regulation or throttling use. For high-speed moving media, the gate can cause vibration of the gate when it is partially opened, and the vibration may damage the sealing surface of the gate and the valve seat, and the throttling will cause the gate to be eroded by the medium. The adaptability of gate valves is stronger than that of butterfly valves, and gate valves can be used in high temperature, low temperature, or high pressure and low pressure conditions. In steam pipelines and large-diameter water supply pipelines, gate valves are more suitable due to the need for higher sealing performance and less fluid resistance.

06

Introduce

OEM & ODM XinHui Gate valves Applications

American standard high temperature and high pressure forged steel gate valve-recommended power station industry

It is suitable for cutting off or connecting the pipeline medium on the pipelines of various systems of petroleum, chemical, hydraulic and thermal power stations with nominal pressure PN1.6~16.0MPa and working temperature ≤-29℃~550℃. Applicable media are: water, oil, steam, acid, alkali, ammonia, urea, sulfur-containing natural gas, etc.

DS-Z44H-Y water seal flange gate valve - recommended for thermal power station industry

BZ41H jacket insulation gate valve-recommended for oil industry

The thermal insulation gate valve is mainly used in various systems such as petroleum, chemical industry, metallurgy, and pharmaceuticals. The jacket of the valve is welded between the two flanges of the valve. The side and bottom of the valve are provided with the connection port of the jacket. Free flow of steam or other hot insulation media ensures smooth flow of viscous media through the valve.

Gas flat gate valve - recommended for natural gas industry

Gas flat gate valve is suitable for natural gas, petroleum, chemical, environmental protection, urban pipelines, gas pipelines and other transportation pipelines, venting systems and gas storage devices, as opening and closing equipment.

Z41F4 F46 Fluorine lined gate valve-recommended for chemical industry

Z41F4 F46 fluorine-lined gate valve adopts large wedge angle design to ensure the service life and make the valve switching torque small. The sealing pair is FPF (F46) / FEP (F46) or other material combination, with low friction coefficient and low opening and closing torque

Strength customers

Testimonials

Gate Valves: Ultimate Guide

Gate valve, also known as gate valve, is mainly composed of valve body, bonnet, gate, valve stem, valve seat and sealing packing. It is one of the common valve types in isolation valves. The main purpose of a gate valve is to shut off fluid, and it is for this reason that it is often referred to as a “block” valve or “blocking” valve.

There are many different structural forms of gate valves, and the types of sealing elements used are different.

According to the structure of the sealing element, it can be divided into several different types.

Classification by stem

According to the valve stem type, it can be divided into open stem gate valve and dark stem gate valve. The valve stem is the operating part of the gate valve, and its function is to transmit the opening and closing force to the opening and closing parts.

- The trapezoidal thread of the stem of the rising stem gate valve is placed outside the valve body and is located on the upper part of the stem. By rotating the stem nut, the stem drives the gate to rise and fall synchronously to realize the opening and closing of the valve, so it is easy to identify the valve.

Open and close state to avoid misoperation. Since the stem nut is outside the body cavity, it is conducive to lubrication, and the opening and closing state is intuitive and obvious, so it is widely used. But in harsh environments, the exposed threads of the valve stem are susceptible to damage and corrosion, which can even affect operation. Its disadvantage is that the height of the valve after opening is large, and a stroke is usually added on the basis of the original height of the valve, so a large operating space is required.

- Concealed stem gate valve, also known as rotating stem gate valve (also called dark stem wedge gate valve), the stem nut is placed inside the valve body and is in direct contact with the medium, and is often fixed on the gate. Through the rotation of the valve stem, the valve stem nut drives the gate to do the lifting movement to complete the opening and closing. Usually there is a trapezoidal thread at the bottom end of the valve stem. Through the thread at the bottom end of the valve and the guide groove on the valve disc, the rotary motion is changed into a linear motion, that is, the operating torque is changed into an operating thrust. Since the trapezoidal thread for transmission is located inside the valve body, it is easily corroded by the medium and cannot be lubricated, and the opening degree cannot be directly observed, and an additional indicating device is required. However, its valve stem does not move up and down, and the required operating space is small, so it is suitable for occasions where the location is limited and the pipeline is dense.

Sort by structure

According to the structure type, it can be divided into two types: wedge gate valve and parallel gate valve.

That is, the wedge gate valve is called a wedge gate valve, and the parallel gate gate valve is a flat gate valve.

- Flat gate valve, that is, the sealing surface is parallel to the vertical centerline, so the sealing surface of the valve body and the gate plate are also parallel to each other. This kind of gate valve is usually a double gate type. In order to make the valve body and the two sealing surfaces of the gate closely contact when closing, a double-sided thrust wedge is often sandwiched between the two gates. Mostly used on low pressure pipelines such as small pipelines. Parallel gate valves with single gate are also available but rare.

- Wedge gate valve is a gate valve in which the sealing surface is at a certain angle with the vertical centerline, that is, the two sealing surfaces are wedge-shaped. Wedge gate valve has single and double gates. The advantage of the double gate type is that the accuracy of the sealing and the angle is lower, the temperature change is not easy to make the gate wedge, and the gasket can be added to compensate for the wear of the sealing surface. The disadvantage is that the structure is complicated, and it is easy to stick in dry medium, and more importantly, the gate plate is easy to fall off after the upper and lower baffles are corroded for many years.

Other ways to classify

- According to different standards: national standard gate valve, American standard gate valve, German standard gate valve, Japanese standard gate valve

- According to the connection method: flange gate valve, welded gate valve, threaded gate valve (also divided into internal thread, external thread)

- According to the pressure level: high pressure gate valve, low (medium) pressure gate valve

- According to the driving mode: electric gate valve, pneumatic gate valve, manual gate valveClassification by material

- stainless steel gate valve

- forged steel gate valve

- cast steel gate valv

- carbon steel gate valve

- cast iron gate valve

- copper gate valve (also divided into bronze gate valve, brass gate valve)

- ceramic gate valve

- plastic gate valve

Generally, the failure of a valve is related to the number of components that make up the valve, and there are many common faults. The second is closely related to the design, manufacture, installation, working conditions, operation, and maintenance of the valve. If the work of each link is accurate, the valve failure will be greatly reduced!

Here are the common failures and treatment methods of the valve.

The valve stem does not move up and down or the switch does not move

Reasons = The valve stem and the nut are too tight, or the matching screw is damaged; the packing gland is biased; when it is cold, it is closed too tightly and it swells to death after being heated or it is too tight when it is fully opened; the packing is too tight; the valve stem gap Too small and swell to death; the door stem is bent; the medium temperature is too high, the lubrication is poor, and the valve stem is severely corroded.

Treatment = Replace the valve stem and nut; after heating the valve body, try to open it slowly or close it when it is fully opened and tight; slightly loosen the packing gland and try to open it; appropriately increase the valve stem clearance; readjust the packing gland bolts ; Straighten or replace the door lever; the door lever is made of pure graphite powder as lubricant.

Valve body leakage

Reason = The valve body has blisters or cracks; the valve body is cracked during repair welding.

Treatment = Polish the suspected crack and etch it with 4% nitric acid solution, if there is a crack, it can be displayed; dig and repair the crack.

The valve core is separated from the valve stem, causing the switch to fail

Reasons = improper repair; corrosion at the junction of the valve core and valve stem; excessive force on the switch, resulting in damage to the combination of the valve core and the valve stem; loose valve core anti-return gasket and wear of the connecting part.

Treatment = pay attention to inspection during maintenance; replace the door lever of corrosion-resistant material; the operation is not to force the switch, or to continue to open the valve after it is not fully opened; check and replace the damaged spare parts.

Internal leakage of the valve

Reasons = damage to the joint surface; poor closing; excessive clearance between the valve core and the valve stem, resulting in sagging or poor contact of the valve core; poor sealing material or jamming of the valve core.

Treatment = valve disintegration, regrinding of valve core and valve seat sealing surface; improve operation, reopen or close; adjust valve core and valve stem clearance or replace valve disc; valve disintegration to eliminate jamming; re-replace or surfacing sealing ring.

There are cracks in the valve core and valve seat

Reason = poor quality of surfacing welding on the joint surface; large temperature difference on both sides of the valve.

Treatment = Repair welding for cracks, heat treatment according to regulations, car polishing, and grinding.

Valve cover joint surface leakage

Reason = the gasket does not meet the requirements or the gasket is damaged; the bolt tightening force is not

enough or tight; the joint surface is defective.

Treatment: replace the gasket; re-tighten the bolts or make the door cover flange clearance consistent; disassemble and repair the door cover sealing surface.

Packing leakage

Reason = the packing gland is not pressed or biased; the packing material is incorrect; the method of adding packing is incorrect; the surface of the valve stem is damaged

Treatment = Check and adjust the packing gland to prevent pressure deviation; select the packing correctly;

add the packing according to the correct method; repair or replace the valve stem.

The valve stem and its matching nut thread are damaged or the stem head is broken, and the valve stem is bent

Reasons = Improper operation, excessive force on the switch, failure of the limit device, no action of the over-torque protection; too loose or too tight thread fit; too many operations and too long service life.

Treatment = Improve the operation, do not use excessive force; check the limit device, check the over-torque

protection devise; select the appropriate material, and the assembly tolerance meets the requirements; replace the spare parts.

The gate valve is also called a pneumatic gate valve or a suction gate valve. The function of the gate valve is to prevent the backflow of the medium in the pipeline. The bottom valve of the water pump suction valve also belongs to the gate valve category. The valve that opens or closes by itself by the flow and force of the medium to prevent the backflow of the medium is called a gate valve. It belongs to the automatic valve category and is mainly used on pipelines where the medium flows in one direction, and only allows the medium to flow in one direction to prevent accidents. The function of the gate valve is to only allow the medium to flow in one direction and prevent the flow in the opposite direction. Usually, this kind of valve works automatically. Under the action of fluid pressure flowing in one direction, the valve flap opens; when the fluid flows in the opposite direction, the fluid pressure and the self-coincident valve flap of the valve flap act on the valve seat, thereby cutting off the flow.

Among them, the gate valve belongs to this type of valve, and the suction gate valve includes a swing gate valve and a lift gate valve. While the gate valve is doing a lot of work, its product quality is very important. The normal operation of the gate valve is the guarantee of continuous work. If you have a spare time, you can check the quality of the gate valve through various testing methods to achieve the purpose of safe work.

So how is the gate valve detected?

We generally divide the most simple method for detecting gate valves into 3 steps:

- Open the gate valve passage, fill the valve cavity with water (or kerosene), and increase the pressure to the pressure required by the strength test. Check the valve body, valve cover, gasket and packing for leakage.

- Close the valve circuit of the exhaust gate valve, pressurize one side of the gate valve to the nominal pressure, and check for leakage from the other side.

- Turn the gate valve upside down and test the opposite side. Through the above three simple steps, it can be analyzed whether the basic working state of the gate valve is abnormal.

Of course, there are more complex inspection methods.

The methods indicated below are aimed at more complex potential problems

The steps can be basically divided into 2 steps:

- The nominal pressure of the gate valve test pressure is from 0.4Mpa-32Mpa. For these common pressure valves, the valve strength test pressure is 1.5 times the nominal pressure. The valve sealing test pressure is equal to 1.1 times the nominal pressure.

- There is usually a pressing part on the gate valve test bench, and a pipeline connected with the pressure test pump below. After the valve is compressed, the pressure test pump works, and the pressure of the valve can be read from the pressure gauge of the pressure test pump. When the gate valve is pressure tested and filled with water, the air in the valve should be drained. The upper pressure plate of the test bench has an exhaust hole, which is opened and closed with a small valve. A sign of clean air is that all that comes out of the vent is water. After closing the vent, start boosting. The boosting process should be slow, not sharp. After reaching the specified pressure, keep it for 3 minutes, and the pressure does not become qualified.

Service life of power station gate valves Due to the wide range of valve applications, various media and different corrosion conditions, the service life of power station gate valves has not been stipulated from national standards to industry standards. The quality of the products and the national high-quality product evaluation, the “Valve Industry Product Quality Grading Regulations” have been formulated, which stipulates the life test requirements for gate valves and cut-off first-class products and superior products; The abrasion

resistance of the first-class product is 2,000 times, and the superior product is 4,000 times. Due to the particularity of gate valves in nuclear power plants, various countries have stipulated the service life of gate valves in nuclear power plants; for example, the United States and France stipulate 40 years, and Japan stipulates 30 to 40 years. Power station gate valve is also called special valve for power station.

Applicable medium: non-corrosive medium such as water and steam. Compared with other valve products, the power station valve is characterized by high temperature and high pressure, and a unique self-sealing design. The higher the pressure, the more reliable the sealing. Due to the special performance and technical characteristics and the special working conditions, the product also has characteristics that cannot be replaced by other products. Can the gate valve be repaired? Yes, but the maintenance cost is more expensive!

Including the cost of the gate valve, labor costs and material costs should be included. If it can be repaired, you can find professional workers to repair it, and the maintenance cost of the gate valve is higher. If you need to purchase a new gate valve, you can contact our XinHui Gate Valve Company!

Advantages of gate valves

- The flow resistance is small, the medium channel inside the valve body is straight, the medium flows in a straight line, and the flow resistance is small.

- It is more labor-saving when opening and closing, which is compared with the globe valve, because whether it is opened or closed, the movement direction of the gate is perpendicular to the flow direction of the medium.

- The height is large, the opening and closing time is long, the opening and closing stroke of the gate is large, and the lifting is carried out by the screw.

- The phenomenon of water hammer is not easy to occur, because the closing time is long.

- The medium can flow in any direction on both sides, which is easy to install, and the two sides of the gate valve channel are symmetrical.

Disadvantages of gate valves

Erosion and scratches are easily caused between the sealing surfaces, and maintenance is difficult. The external size is large, a certain space is required to open, and the opening and closing time is long. The structure is more complicated.

The difference between a gate valve and a globe valve can be distinguished from the appearance, that is, the gate valve has no direction of flow. The globe valve has a flow direction!