valve end connection types

valve end connection types

valve end connection types are usually divided into: threaded, flanged, welded, clamp and ferrule. Threaded connection is a detachable connection, and it is not suitable for welding or needs to be disassembled. Threaded connection is mostly used. For >DN50 threaded connection, it can be used for non-hazardous fluids, but its connection is not easy to control, and it is difficult to apply enough without damaging the components. The torque is used to tighten the connection joint, so the threaded connection is mostly used in pipelines with no dangerous fluids of ≤DN50.

-

Control valves

Boiler feed water control valve

-

Control valves

DTO high plus desperate steam trap control valve

-

Control valves

High pressure angle type control valve

-

Control valves

Urea synthesis tower outlet pressure control valve

-

Control valves

Boiler feed pump minimum circulating flow control valve

-

Control valves

Steam hydrophobic control valve

-

Control valves

Liquid Nitrogen Control Valve

-

Control valves

High temperature steam trap control valve

why choose newinteg valve !

Our wish is to get you here without having to look for anyone else!

Full range of valve types

We have hundreds of industrial valves for you to choose from!

Novel valve type

Every year research and development of novel valves are put into production!

Customized valve types

Fully customized valve according to customer needs!

valve end connection types

VALVE CONNECTION TYPE

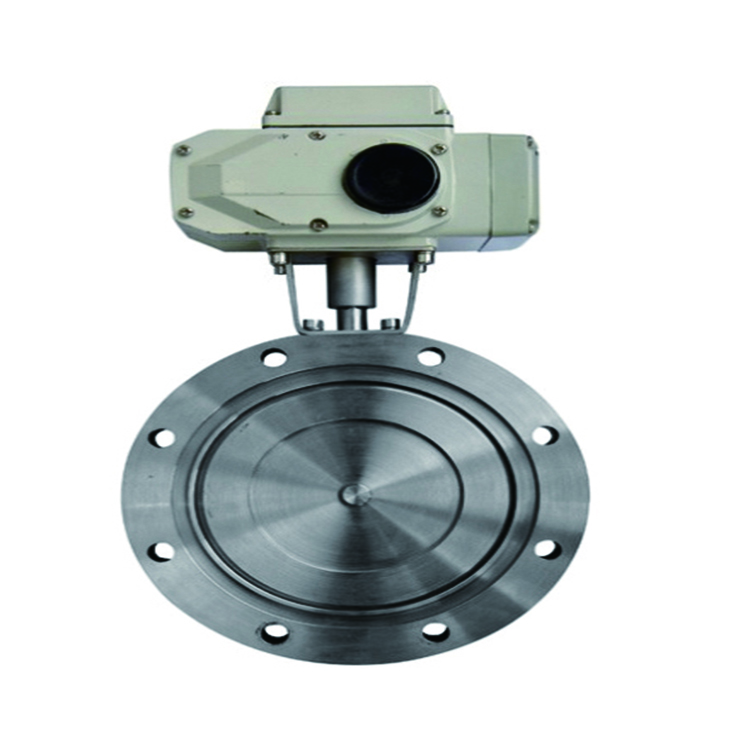

Flange connection

Wafer connection

Welding connection

Valve socket welding connection

Threaded connection

Terminal connection

Internal self-locking valve connection

More Valve related articles

I believe you will not regret your choice

Why choose XinHui valve?

Customized on demand

We very much welcome customers to bring your requirements in the industry, our industrial valve solutions include customized on demand! Use the best materials to produce standard compliant valves, If you need valve customization services, please contact us immediately

Valve quality

Xinhui valve strictly controls the quality of the products in each process; on the other hand, it improves the work quality of the employees; and constantly pursues the high performance and high quality of the products, and is committed to becoming the preferred brand of valve products for the majority of users. .

Professional Services

Our salesman will answer your professional industry questions, product questions, transportation questions, etc. Our service personnel are online 7*12 hours. If you encounter time difference problems, please wait patiently for our reply, and we will reply you as soon as possible The problem.

High and new technology

As a high-tech enterprise in China, we can provide complete valve sample drawings, technical support for valve production process, technical support such as maintenance manuals, and strength calculation books. Frequently Asked Questions about Valve Operation.

R&D innovation

Xinhui Valve has invested a lot of manpower and funds in the innovative research and development of valves, and opened laboratories, inspection rooms, and R&D rooms. 20 kinds of new products are developed every year. Customized industry-specific valves for customers, dozens of products under severe valve conditions.

International Standard

The valves we produce meet various international testing indicators, and all kinds of valves are manufactured and accepted according to relevant domestic standards such as GB and JB, as well as international standards such as ANSI, API, JIS, and BS. DIN. Please contact us for special production standards.

We are not only a manufacturer of valves, but also a disseminator of industry knowledge

OEM & ODM Newinteg Butterfly valve Applications

D341F Fluorine Lined Flanged Butterfly Valve - Recommended for Chemical Industry

As a component used to realize the on-off and flow control of the pipeline system, the fluorine-lined flange butterfly valve is widely used in the petroleum field. Suitable for various concentrations of aqua regia, sulfuric acid, hydrochloric acid, hydrofluoric acid and various organic acids, strong acids, strong oxidants at -50℃~150℃, FEP flange lined fluorine butterfly valve is suitable for various concentrations of strong alkali organic solvents And other corrosive gas, liquid medium pipeline use.

HBD741X(H) Hydraulic Controlled Slow Closing Check Butterfly Valve-Recommended for power station industry

The hydraulically controlled slow-closing check butterfly valve is also a relatively good pipeline control equipment in China. It is mainly installed at the turbine inlet of the hydropower station industry and used as the turbine inlet valve. Therefore, since the hydraulically controlled slow-closing check butterfly valve has been developed, it has replaced the functions of the check valve and the gate valve. Through the preset opening and closing procedures, in this way, the reliable cut-off of the pipeline is realized, the water hammer of the pipeline is effectively eliminated, and the safety of the pipeline system is protected.

D363H Butt Welded Metal Hard Seat Butterfly Valve-Recommended for metallurgical industry

D363H butt welding hard sealing butterfly valve is widely used in metallurgy, electric power, petrochemical industry, water supply and drainage and municipal construction and other industrial pipelines with medium temperature ≤425℃. It adopts precise J-shaped elastic sealing ring and triple eccentric multi-layer metal hard sealing structure, which is used for regulating flow and load-cutting fluid. The valve seat and disc sealing surface are made of different hardness and stainless steel, which have good corrosion resistance. Long life, the valve has bidirectional sealing function

NKD943X double seal vacuum butterfly valve-recommended for chemical and pharmaceutical industries

NKD343X double-sealed vacuum butterfly valve is a new generation of high-tech products successfully developed by our company in combination with new vacuum technology standards at home and abroad.

The valve structure is designed as: double butterfly plate, double sealing seat, three-dimensional eccentric locking structure, cobalt-based hard alloy surfacing on the sealing surface of the valve body, and the sealing ring is made of temperature-resistant, corrosion-resistant rubber and fluorine rubber pressure plate firmly sealed Pressed on the butterfly plate can be removed and replaced for easy maintenance

Top Entry Type Two-way High Pressure Metal Hard Seal Butterfly Valve-Recommended for Petroleum Industry

The top-mounted two-way high-pressure metal hard-sealed butterfly valve has the advantages of simple structure, low cost, convenient maintenance, and does not affect the normal operation of the pipeline system during maintenance.

valve end connection types: Ultimate Guide

METHODS OF CONNECTING THE VALVE

Threaded connection

Accumulation of sand, dirt or any foreign material in the pipeline can hinder valve efficiency and severely damage critical valve components. The inside of the pipe must be thoroughly cleaned with air or steam and, when tapping the pipe, it is necessary to measure the size and length of the pipe thread to avoid filling the pipe with the valve seat and the valve disc .

It is also important to wash the threaded ends thoroughly to remove any harmful steel or iron deposits.If, on the other hand, you want a stronger weld, you can use Teflon tape or adhesive for pipes, but only sparingly on the pipe threads, never on the valve threads and not even in the valve body to avoid damage to the disc and seat.

Before installation, close the flow through the valve to allow proper operation and close the valve completely before installation. Place a wrench over the head of the hexagonal bolt near the pipe to avoid possible deformation, finally after installing the valve a support must be placed for the pipe as the yielding pipes can deform the valve and cause it to fail.

Flanged connection

To ensure correct connection and installation of the valve flange, precise and organized steps are necessary:

- Thoroughly clean the joints.

- Loosely install two or three bolts on the base.

- Carefully insert the spacer into the joint (the lower bolts help locate the gasket and hold it in place).

- Tighten inserted bolts crosswise and NOT round to help eliminate excessively concentrated pressure.

- After a period of normal use, check if all bolts are tight and retighten if necessary.

Low temperature welding and silver brazing

Before installing the correct valve it is necessary and appropriate to read the installation instructions.

- First cut the pipe in the vertical direction and remove the burrs by measuring the diameter of the pipe.

- Use gauze or wire brush to remove debris and cut parts so that the metal surface shines.

- Apply flux to the outside of the pipe and inside the welding hood, which must completely cover the welding surface.

- Make sure the valve is open, heat the pipes first and then transfer as much heat as possible from the pipe to the valve without extending the heating time of the valve itself.

Silver Brazing Method

Assemble the parts to be brazed remembering that if the fluxed part is left standing, the

moisture in the flow will evaporate and the dry flux will peel off easily, leaving exposed metal surfaces susceptible to oxidation. When making a connection assembly you must insert the tube into the socket until it encounters a block: the assembly serves to ensure a firm support so that it remains in a straight position during the brazing operation.

REMEMBER: For valves with a nominal diameter of 1 inch or larger it is difficult to heat the

connecting parts to the desired temperature at one time! Two torches are usually required

to maintain a normal temperature over a large area, which is why we recommend adequate preheating of the entire surface of the coating and using an acetylene flame to heat the connected parts.

Do this: start by heating the tube 1 inch from the valve, then alternately cook the tube up

and down a short distance around the tube, turning the tube at the correct angle to avoid

burning the tube (the flame must move continuously, do not leave it in a fixed point).

Heat evenly until the flow over the valve no longer makes any sound, but be careful not to

overheat the valve!

When the flow becomes liquid and appears translucent on the pipes and valves, start cooking the flame back and forth along the axis of the connecting parts to keep the connecting parts warm, especially the valve sleeve seat.

- Use the right amount of solder

If too much solder is used, some of the solder may flow past the pipe barrier and clog the sealing area (note that the solder and braze continues to flow as the connecting parts are installed)

Silver Brazing Method

Point the welding wire or welding rod at the pipe socket in the valve and move the flame

away from the welding rod or wire as it enters the joint. Now proceed by moving the

flame back and forth as the alloy flows into the joint and once the proper temperature

is reached you will notice that the alloy flows quickly and easily into the gap between the

tube housing and the valve sleeve. Once the joint is filled, the edge of the welded alloy

is visible.

6.Use a brush to remove the excess solder

When the solder is tacky, use a brush to remove the excess solder while after the solder has

cooled, wrap a thread around the valve port.

Silver Brazing Method

If different brazing materials are used, the strength of the brazed connection may not be

optimal, but its strength depends on how the cleaning and maintenance work has been

carried out between the tube shell and the valve housing. The mechanical tolerances and

surface smoothness of the inner diameter of the bushings of the silver brazed valves are very

precise, in order to ensure adequate adhesion.

REMEMBER: During the cleaning and removal process, detergent residues must be carefully

observed! If the soldering takes place on dirty or unclean surfaces then the silver brazing alloy

does not flow or adhere to the oxides, while the oily and exposed surfaces will oxidize easily:

what will happen is that the debris will reject the flow.

- Thread for cylindrical pipes with general sealing

- Thread for conical tubes with general sealing

RF is called a Raised face. The raised area of the flange faces which contains the gasket sealing surface between mating flanges. This RF flange is the most common type that is used in plants application and it is very easy to identify.

The purpose of RF end connections is to concentrate more pressure on smaller areas. It helps in increasing pressure joint capability.

NPT end connections are also known as national pipe thread tapered connections. This is United States standards for tapered threads that are used on threaded fittings and pipes. These are found on a taper, on a bolt thread will pull it tight and hence make a tight seal.

NPT end connections rely on thread deformation from a metal to metal sealing design where the connector’s threads connect together.

Valves are manufactured and made with many end connection types that include socket welded, screw end, flanged and butt welds. Special connection can be done and it can be specified such as grooved, union, and with other connectors.

Screw end valves need very less labor connections; it also costs very less for other types. These valve end connections are used on valves that are made of steel and have a socket with an inner diameter that is larger than the pipe’s outer diameter.