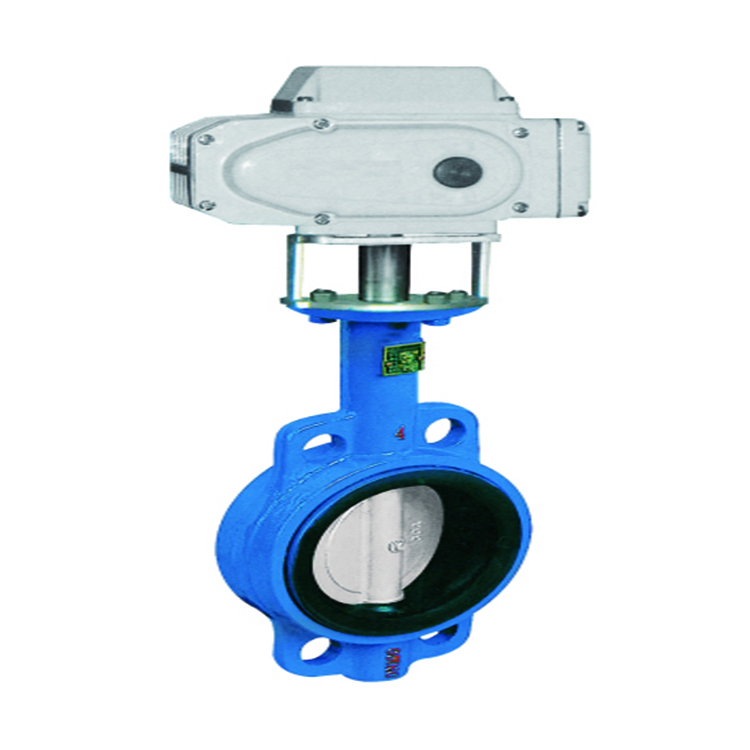

| Brand | XinHun | Custom processing | yes |

|---|---|---|---|

| Connection Type | pair clip | material | Carbon steel, stainless steel, brass, cast iron, cast copper, ductile iron, alloy steel, copper alloy, plastic, ceramic, PPR, PVC, fluorine-lined, copper |

| Applicable media | Water, steam, oil, various highly corrosive chemical media, weak acid and alkali media, ammonia, nitrogen, oxygen, hydrogen, liquefied gas, air, coal gas, dusty gas | stress environment | normal pressure |

| working temperature | high temperature | Flow direction | two-way |

| drive mode | electron | Parts and Accessories | Locator |

| shape | butterfly type | type | two-way |

| sealed form | soft sealing | structure type | vertical plate type |

| Nominal diameter | 50-4000mm | caliber | 50-4000 |

| Installation size | 50-4000 |

detail introduction

The technical solution of the utility model is that there is a casing and an upper cover connected to the casing, the main shaft installed in the casing is connected to the handwheel through the upper cover, a sealing device is arranged between the upper cover and the main shaft, and a tooth is arranged at the lower end of the upper cover There are teeth on the upper end of the groove and the main body to form a clutch, the main body is connected with the main shaft through a key, the lower part of the main shaft is provided with a return spring, the lower end of the main body is connected with the valve stem, and the bottom surface of the shell is connected with the flange of the wafer type rubber-lined butterfly valve.

1. The valve adopts double eccentric structure, which has the sealing function of tighter and tighter, and the sealing performance is reliable.

2. The sealing material is made of stainless steel and butyl oil-resistant rubber, which has a long service life.

3. The rubber sealing ring can be located on the valve body or on the butterfly plate, and can be applied to media with different characteristics for users to choose.

4. The butterfly plate adopts frame structure, which has high strength, large flow area and small flow resistance.

5. The overall paint can effectively prevent corrosion and can be used for different media as long as the sealing material of the sealing valve seat is replaced.

6. The valve has a two-way sealing function. It is not controlled by the flow direction of the medium during installation, nor is it affected by the spatial position. It can be installed in any direction.

7. The valve has a unique structure, flexible operation, labor-saving and convenient.

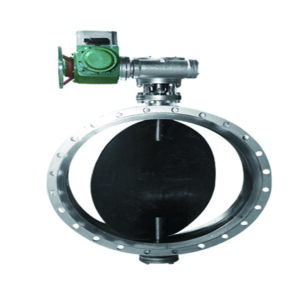

It rotates around the axis, and the rotation angle is between 0° and 90°. When it rotates to 90°, the valve is fully open. Electric soft sealing butterfly valve is simple in structure, small in size and light in weight, and only consists of a few parts. And it only needs to rotate 90° to open and close quickly, the operation is simple, and the electric valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the maximum resistance when the medium flows through the valve body, so the pressure drop generated by the valve is very small, so it has better flow control characteristics. Butterfly valves have two types of seals: elastic seal and metal seal. Elastic sealing valve, the sealing ring can be inlaid on the valve body or attached to the periphery of the disc. If the butterfly valve is required to be used as flow control, the main thing is to correctly select the size and type of the valve. The structure principle of the butterfly valve is especially suitable for making large-diameter valves. Butterfly valves are not only widely used in general industries such as petroleum, gas, chemical, and water treatment, but also in cooling water systems in thermal power plants. Similar products also include pneumatic soft-sealed butterfly valves and manual soft-sealed butterfly valves.

executive body

The electric soft-sealed butterfly valve has a small operating torque, which is the smallest operating torque among all valves. It is the execution unit of the instrument in the automatic control system. It is powered by AC220V, AC380V or DC24V power supply voltage, and accepts from (DCS, PLC) system or The operation can be controlled by adjusting the current signal or voltage signal (4-20mA, 0-10mA or 1-5VDC) input by the instrument and operator. Turning the valve shaft 0~90° with the torque output by the angular stroke can complete the opening and closing action or the adjustment action.

|

product name |

Electric butterfly valve |

|||

|

function type |

Switching type Adjustable type |

|||

|

Connection Type |

Flange Type Wafer Type Pipe Thread Type |

|||

|

structure type |

Three-dimensional eccentric type |

midline shaped structure |

Two eccentric type |

Three-dimensional eccentric type |

|

|

multi-level structure |

|

Elastic seat structure |

|

|

Valve seat sealing form |

Soft Seal, Carbide Seal |

soft sealing |

Soft Seal, Carbide Seal |

|

The centerline structure is composed of valve body, inner lining layer (polytetrafluoroethylene or rubber), (stainless steel valve plate or chrome-plated steel valve plate), and valve shaft. , The sealing structure is a centerline seal, the sealing performance is reliable, and the two-way seal is zero leakage. It can be installed at any position.

Features:

1. Powerful functions: intelligent, adjustable, switch.

2. Small size: The volume is only equivalent to about 35% of similar products.

3. Easy to use: single-phase power supply, simple wiring; the use of a unique ball-shaped protruding structure, making observation more convenient; no oil, no spot inspection, waterproof and rust-proof, and can be installed at any angle.

4. The protection device has double limit, overheat protection and overload protection. The full travel time is 15 seconds, 30 seconds, 45 seconds, 60 seconds. And with manual function.

5. Intelligent numerical control: The built-in module adopts advanced computer single chip and intelligent control software to directly receive the standard signal (4-20mA DC/1-5VDC) output by computer or industrial instrument to realize intelligent control and precise positioning of valve opening. 3810 series or NA series electronic angular stroke actuators can also be selected. PSQ series or DYR series can also be selected.

Material of main parts

|

Part Name |

Material |

|

valve body |

HT250 WCB SUS304 |

|

Butterfly board |

Ductile Iron Nickel Phosphorus Plated Stainless Steel 304, 316 |

|

valve shaft |

2Cr13 SUS304 |

|

sealing ring |

NBR、EPDM、VITON、PTFE |

Executive standard

|

Manufacturing Standards |

GB/T 122387-89 |

|

Flange Standard |

GB9113-2000、GB17241.6-1998 |

|

Structure length standard |

GB12221-89 |

|

Inspection standards 检验标准 |

GB/T 13927-92 |

D971X Electric Wafer Type Soft Seal Butterfly Valve Main Outline and Connection Dimensions

|

DN |

L |

H |

H1 |

A |

B |

ФD |

|

0.6MPa |

1.0MPa |

1.6MPa |

|

|

|

|

|

50 |

43 |

77 |

443 |

125 |

125 |

88 |

|

65 |

46 |

85 |

463 |

125 |

125 |

108 |

|

80 |

46 |

95 |

483 |

125 |

125 |

124 |

|

100 |

52 |

105 |

498 |

125 |

125 |

144 |

|

125 |

56 |

129 |

682 |

325 |

245 |

174 |

|

150 |

56 |

132 |

736 |

325 |

245 |

199 |

|

200 |

60 |

165 |

800 |

325 |

245 |

254 |

|

250 |

68 |

197 |

895 |

363 |

313 |

309 |

|

300 |

78 |

234 |

956 |

363 |

313 |

363 |

|

350 |

78 |

283 |

1029 |

363 |

313 |

413 |

|

400 |

102 |

325 |

1103 |

363 |

313 |

463 |

|

450 |

114 |

369 |

1186 |

465 |

469 |

518 |

|

500 |

127 |

404 |

1280 |

546 |

431 |

568 |

|

600 |

154 |

470 |

1321 |

546 |

556 |

667 |

|

700 |

165 |

503 |

1431 |

546 |

556 |

772 |

|

800 |

190 |

571 |

1542 |

546 |

556 |

878 |

|

900 |

203 |

621 |

1800 |

617 |

706 |

978 |

|

1000 |

216 |

702 |

2363 |

632 |

706 |

1078 |

|

1200 |

254 |

818 |

2583 |

632 |

706 |

1295 |

Reviews

There are no reviews yet.