Empty Exhaust Check Valve Factory

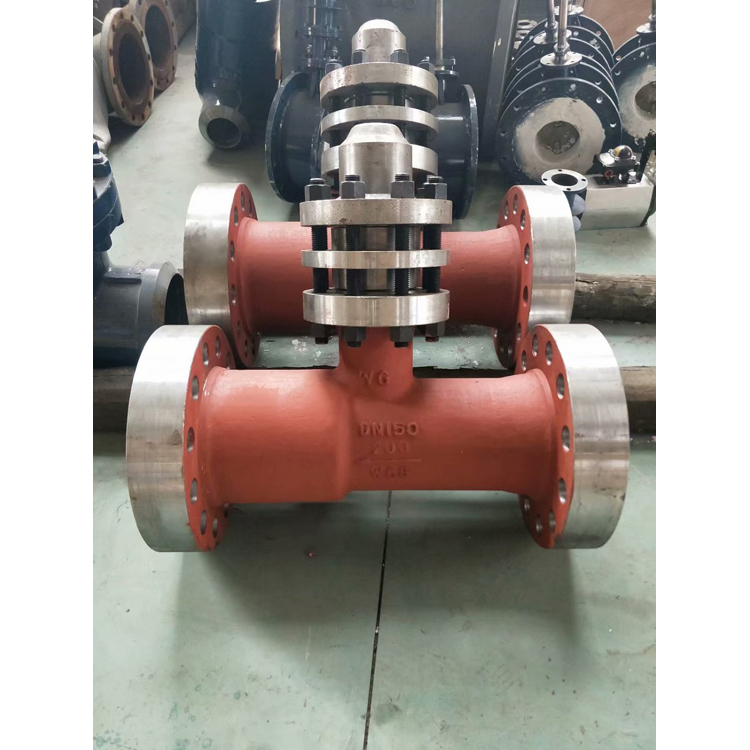

No-load running check valve(Description)

All parts of the valve are forgings, and the forging is carried out strictly in accordance with the forging process rules and process cards. The initial forging temperature, final forging temperature, deformation degree and deformation speed are strictly controlled, and the cooling method specified in the process rules is cooled. The chemical composition analysis, mechanical property test, intergranular corrosion test and metallography analysis of the forged products were carried out.

The quality of forgings is guaranteed by ultrasonic inspection and liquid penetration inspection. According to the requirements of RCC-M, 100% ultrasonic inspection and evaluation of forgings are carried out, and all the surfaces of forgings are inspected and evaluated by liquid penetration inspection.

Working principle

Open the outlet valve and start the water pump. After the water supply reaches a certain pressure, the valve core will automatically rise and push away from the valve seat, and the water supply will flow out. At the same time, the valve core connecting rod pulls the drain port and the valve plate closes the drain port. When the flow rate of the water pump decreases, the valve core falls, and the connecting rod is pushed to pull out the exhaust valve sheet, and the recirculation door is opened to maintain the small flow rate of the water pump. When the pump is stopped, the valve core automatically falls down to close the channel, so as to prevent the damage of high pressure water hammer to the water supply system.

Structural features

a.The valve works with the recirculation bypass valve to maintain the safe operation of the system.

b.The main valve disc moves up and down, and when the medium flows back, the channel is closed under the action of medium pressure and spring. At this time, the bypass valve is open. When the main valve disc is fully open, the bypass valve is closed.

c.The disc seal is made of stainless steel surfacing, wear resistance, abrasion resistance, reliable sealing.

d.The valve should be installed vertically

Specifications

| Nominal pressure PN/MPa | Shell test pressure Ps/MPa | Working pressure PN/MPa | Applicable medium | Operating temperature /℃ |

| 20.O | 30.O | 20.O | water | ≤160 |

Material of main parts

| Name | Material |

| Valve body, positioning wheel, connecting flange, exhaust flange, flange cover | Carbon cast steel |

| Guide shaft, fork, shaft sleeve, slide block, discharge sleeve, exhaust plate | Stainless steel |

| Bolts, studs | Hascrome |

| Lining | Casting aluminium bronze |

| Disc, disc body, disc shaft, connecting fork, screw nut | Quality carbon steel |

Reviews

There are no reviews yet.