product description

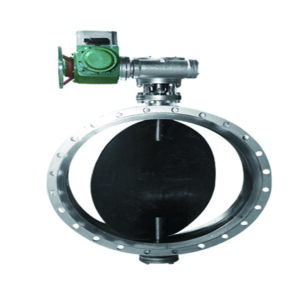

Based on the introduction of foreign technology, D363H butt-welding hard sealing butterfly valve adopts precise J-shaped elastic sealing ring and triple eccentric multi-layer metal hard sealing structure. It is widely used in metallurgy, electric power, petrochemical, etc. As well as industrial pipelines such as water supply and drainage and municipal construction, it is used for regulating flow and load-cutting fluid. D363H butt welding hard sealing butterfly valve adopts triple eccentric structure, the valve seat and disc plate sealing surface are made of different hardness and stainless steel, which has good corrosion resistance and long service life. T13927-92 Valve Pressure Test Standard. D363H Butt Welding Hard Seal Butterfly Valve is suitable for heating pipes, oil and gas pipelines and other main industrial pipeline valves. This design makes the valve an ideal hard seal butterfly valve for high temperature and fire protection.

use

D363H butt welding hard sealing butterfly valve is suitable for food. Medicine, petrochemical, power plants, steel mills, industrial environmental protection water treatment and high-rise buildings. It is the best device for adjusting the flow and cutting off the fluid on the water supply and drainage pipes. Butterfly valve is suitable for opening and closing or regulating medium on high temperature, high pressure, fire prevention, heat preservation and other pipelines.

main feature

1. Compact structure, small size, light weight, flexible operation and convenient use

2. The three-dimensional eccentric elastic or multi-layer hard sealing structure is adopted, and its sealing performance is reliable and achieves zero leakage.

3. This valve cannot be flanged, and it is very convenient and beautiful to be wrapped with pipes and Baoba

4. It has the characteristics of high temperature resistance, high pressure corrosion resistance, wear resistance, etc.

Transmission type: worm gear drive, pneumatic drive, electric drive

Adopt standard

Welding size: GB12224; ANSI B16.25; DIN2559

Structure length: GB/T12221-1989; API609

Pressure test: GB/T13927-1992; API598

The main technical parameters

|

Nominal diameter |

DN(mm) |

80~2000 |

||||

|

Nominal pressure |

PN(MPa) |

0.6 |

1.0 |

1.6 |

2.5 |

4.0 |

| testing pressure

Ps(MPa) |

Strength test |

0.9 |

1.5 |

2.4 |

3.75 |

6.0 |

|

sealing test |

0.66 |

1.1 |

1.76 |

2.75 |

4.4 |

|

|

Air tightness test |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

|

|

Applicable media |

Water, steam, oil, acid corrosive, etc. |

|||||

|

Applicable temperature |

Carbon steel: -29℃~425℃ Stainless steel: -40℃~600℃

|

|||||

Main parts and materials

|

Part Name |

Material |

|

valve body |

Cast steel, stainless steel, chrome molybdenum steel and special materials |

|

butterfly board |

Cast steel, alloy steel (hard chrome plated), stainless steel, chrome molybdenum steel and special materials |

|

sealing ring |

Stainless steel, anti-wear material |

|

valve stem |

2Cr13, 1Cr13 stainless steel, chrome molybdenum steel |

|

packing |

Flexible graphite |

Main outline and connection size

|

Nominal pressure |

PN0.6 |

||||||||

|

Nominal diameter |

External Dimensions (Reference Value) |

Reference weight (kg) |

|||||||

|

mm |

inch |

L |

D |

d |

H |

H1 |

A1 |

B1 |

|

|

600 |

24 |

390 |

636 |

602 |

499 |

1280 |

570 |

660 |

– |

|

700 |

28 |

430 |

726 |

692 |

566 |

1480 |

750 |

550 |

– |

|

800 |

32 |

470 |

826 |

792 |

632 |

1608 |

750 |

550 |

780 |

|

900 |

36 |

510 |

926 |

892 |

693 |

1857 |

750 |

550 |

820 |

|

1000 |

40 |

550 |

1028 |

992 |

757 |

2038 |

900 |

750 |

1460 |

|

1200 |

48 |

630 |

1228 |

1192 |

851 |

2237 |

1000 |

925 |

1590 |

|

1400 |

56 |

710 |

1428 |

1392 |

876 |

2411 |

1000 |

925 |

2185 |

|

1600 |

64 |

790 |

1628 |

1592 |

1095 |

2756 |

1000 |

925 |

3210 |

|

1800 |

72 |

870 |

1828 |

1792 |

1214 |

3093 |

1100 |

980 |

4090 |

|

2000 |

80 |

950 |

2028 |

1992 |

1332 |

3355 |

1100 |

980 |

5610 |

|

Nominal pressure |

PN1.0 |

||||||||

|

Nominal diameter |

External Dimensions (Reference Value) |

Reference weight (kg) |

|||||||

|

mm |

inch |

L |

D |

d |

H |

H1 |

A1 |

B1 |

|

|

600 |

24 |

390 |

636 |

602 |

499 |

1280 |

570 |

660 |

465 |

|

700 |

28 |

430 |

726 |

692 |

566 |

1480 |

750 |

550 |

680 |

|

800 |

32 |

470 |

826 |

792 |

632 |

1608 |

750 |

550 |

810 |

|

900 |

36 |

510 |

926 |

892 |

693 |

1857 |

750 |

550 |

860 |

|

1000 |

40 |

550 |

1028 |

992 |

757 |

2038 |

900 |

750 |

1625 |

|

1200 |

48 |

630 |

1228 |

1192 |

851 |

2237 |

1000 |

925 |

1770 |

|

1400 |

56 |

710 |

1428 |

1392 |

876 |

2411 |

1000 |

925 |

2426 |

|

1600 |

64 |

790 |

1628 |

1592 |

1095 |

2756 |

1000 |

925 |

3560 |

|

1800 |

72 |

870 |

1828 |

1792 |

1214 |

3093 |

1100 |

980 |

4545 |

|

2000 |

80 |

950 |

2028 |

1992 |

1332 |

3355 |

1100 |

980 |

6230 |

|

Nominal pressure |

PN1.6 |

||||||||

|

Nominal diameter |

External Dimensions (Reference Value) |

Reference weight (kg) |

|||||||

|

mm |

inch |

L |

D |

d |

H |

H1 |

A1 |

B1 |

|

|

80 |

3 |

180 |

90 |

78 |

90 |

356 |

180 |

200 |

27 |

|

100 |

4 |

190 |

110 |

96 |

100 |

375 |

180 |

200 |

34 |

|

125 |

5 |

200 |

135 |

121 |

113 |

401 |

180 |

200 |

41 |

|

150 |

6 |

210 |

161 |

146 |

130 |

450 |

270 |

280 |

43 |

|

200 |

8 |

230 |

222 |

202 |

205 |

545 |

400 |

425 |

81 |

|

250 |

10 |

250 |

278 |

254 |

235 |

630 |

400 |

425 |

102 |

|

300 |

12 |

270 |

330 |

303 |

275 |

715 |

450 |

560 |

132 |

|

350 |

14 |

290 |

382 |

351 |

309 |

817 |

450 |

560 |

164 |

|

400 |

16 |

310 |

432 |

398 |

346 |

923 |

535 |

580 |

193 |

|

450 |

18 |

330 |

484 |

450 |

932 |

1059 |

535 |

580 |

238 |

|

500 |

20 |

350 |

535 |

501 |

427 |

1126 |

535 |

580 |

302 |

|

600 |

24 |

390 |

636 |

602 |

509 |

1369 |

570 |

660 |

457 |

|

700 |

28 |

430 |

726 |

692 |

572 |

1492 |

750 |

550 |

810 |

|

800 |

32 |

470 |

826 |

792 |

638 |

1622 |

750 |

550 |

1093 |

|

900 |

36 |

510 |

926 |

892 |

700 |

1924 |

750 |

550 |

1410 |

|

1000 |

40 |

550 |

1028 |

992 |

765 |

2054 |

900 |

750 |

1870 |

|

1200 |

48 |

630 |

1228 |

1192 |

860 |

2259 |

1000 |

925 |

2082 |

|

1400 |

56 |

710 |

1428 |

1392 |

986 |

26, 10 |

10, 00 |

925 |

2850 |

|

1600 |

64 |

790 |

1628 |

1592 |

1106 |

2856 |

1000 |

925 |

4235 |

|

1800 |

72 |

870 |

1828 |

1792 |

1226 |

3121 |

1100 |

980 |

5346 |

|

2000 |

80 |

950 |

2028 |

1992 |

1345 |

3385 |

1100 |

980 |

7328 |

|

Nominal pressure |

PN2.5 |

||||||||

|

Nominal diameter |

External Dimensions (Reference Value) |

Reference weight (kg) |

|||||||

|

mm |

inch |

L |

D |

d |

H |

H1 |

A1 |

B1 |

|

|

80 |

3 |

180 |

90 |

78 |

90 |

356 |

180 |

200 |

38 |

|

100 |

4 |

190 |

110 |

96 |

106 |

387 |

180 |

200 |

40 |

|

125 |

5 |

200 |

135 |

121 |

122 |

413 |

180 |

200 |

60 |

|

, 150 |

6 |

210 |

161 |

146 |

136 |

459 |

270 |

280 |

65 |

|

200 |

8 |

230 |

222 |

202 |

215 |

585 |

400 |

425 |

85 |

|

250 |

10 |

250 |

278 |

254 |

247 |

649 |

400 |

425 |

135 |

|

300 |

12 |

270 |

330 |

303 |

288 |

771 |

450 |

560 |

175 |

|

350 |

14 |

290 |

382 |

351 |

333 |

929 |

450 |

560 |

195 |

|

400 |

16 |

310 |

432 |

398 |

359 |

993 |

535 |

580 |

295 |

|

450 |

18 |

330 |

484 |

450 |

405 |

1053 |

535 |

580 |

350 |

|

500 |

20 |

350 |

535 |

501 |

444 |

1245 |

535 |

580 |

510 |

|

600 |

24 |

390 |

636 |

602 |

521 |

1750 |

570 |

660 |

625 |

|

700 |

28 |

430 |

726 |

692 |

586 |

1519 |

750 |

550 |

925 |

|

800 |

32 |

470 |

826 |

792 |

659 |

1659 |

750 |

550 |

1260 |

|

900 |

36 |

510 |

926 |

892 |

720 |

1829 |

750 |

550 |

1790 |

|

1000 |

40 |

550 |

1028 |

992 |

780 |

1949 |

900 |

750 |

1940 |

|

1200 |

48 |

630 |

1228 |

1192 |

889 |

2243 |

1000 |

925 |

2810 |

|

1400 |

56 |

710 |

1428 |

1392 |

1000 |

2462 |

1000 |

925 |

3500 |

|

Nominal pressure |

PN4.0 |

||||||||

|

Nominal diameter |

External Dimensions (Reference Value) |

Reference weight (kg) |

|||||||

|

mm |

inch |

L |

D |

d |

H |

H1 |

A |

B |

|

|

80 |

3 |

180 |

90 |

78 |

108 |

430 |

180 |

200 |

39 |

|

100 |

4 |

190 |

110 |

96 |

108 |

392 |

180 |

200 |

50 |

|

125 |

5 |

200 |

135 |

120 |

120 |

414 |

180 |

200 |

75 |

|

150 |

6 |

210 |

161 |

145 |

135 |

494 |

270 |

280 |

100 |

|

200 |

8 |

230 |

222 |

200 |

202 |

578 |

400 |

425 |

135 |

|

250 |

10 |

250 |

278 |

252 |

235 |

673 |

400 |

425 |

190 |

|

300 |

12 |

270 |

330 |

301 |

280 |

793 |

450 |

560 |

240 |

|

350 |

14 |

290 |

382 |

351 |

315 |

921 |

450 |

560 |

320 |

|

400 |

16 |

310 |

432 |

398 |

355 |

1021 |

535 |

580 |

450 |

|

450 |

18 |

330 |

484 |

448 |

370 |

1143 |

535 |

580 |

500 |

|

500 |

20 |

350 |

535 |

495 |

420 |

1192 |

535 |

580 |

560 |

|

600 |

24 |

390 |

636 |

595 |

490 |

1327 |

570 |

660 |

720 |

Reviews

There are no reviews yet.