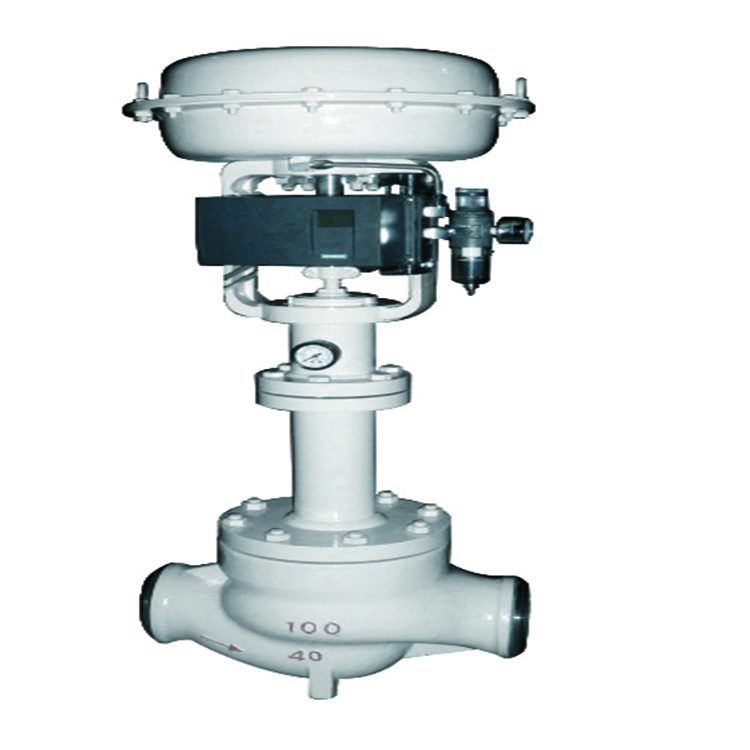

HTSW Bellows Control Valve Product Overview

HTSW bellows sealed single-seat control valve belongs to CV3000 series of control valve products. The valve core adopts an upper-guided single-seat plunger structure, and the upper bonnet adopts a bellows sealing structure to prevent the medium in the pipeline from leaking from the valve stem and packing seal. . The bellows are made of high-quality stainless steel, which is anti-corrosion and has a long service life. The packing will age and wear over time, and it forms a double seal with the bellows, which greatly improves the reliability. The flow channel of the valve body is S-shaped, with small flow resistance and large flow. Especially suitable for strong corrosive, toxic and radioactive media. Assembled with ZHA multi-spring membrane actuator, the structure is compact and the output force is large.

HTSW Bellows Control Valve Features

1 Single-seat plunger type valve core, small leakage, and small allowable pressure difference.

2. The adjustment mechanism can be equipped with a straight-stroke electric actuator to form electric bellows sealed single-seat control valve.

3. The bellows and packing are double sealed to effectively prevent the leakage of the medium.

HTSW Bellows Control Valve Main Technical Parameters

|

Nominal diameter |

40 |

50 |

65 |

80 |

100 |

150 |

||||||||||||

|

Seat Diameter |

25 |

32 |

40 |

32 |

40 |

50 |

40 |

50 |

65 |

50 |

65 |

80 |

65 |

80 |

100 |

100 |

125 |

150 |

|

High precision valve core |

10 |

14 |

24 |

17 |

24 |

44 |

24 |

44 |

68 |

44 |

68 |

69 |

68 |

99 |

175 |

175 |

275 |

360 |

|

High capacity valve core |

|

|

30 |

|

|

50 |

|

|

85 |

|

|

125 |

|

|

200 |

|

|

420 |

|

Quick open valve core |

|

|

35 |

|

|

55 |

|

|

95 |

|

|

135 |

|

|

220 |

|

|

460 |

|

Nominal pressure Mpa |

1.6, 2.5, 4.0, 6.4 |

|||||||||||||||||

|

stroke mm |

25 |

38 |

50 |

|||||||||||||||

|

Stroke, quick opening mm |

10 |

13 |

19 |

25 |

30 |

|||||||||||||

|

Flow characteristics |

straight line, equal percentage |

|||||||||||||||||

|

Operating temperature |

Normal temperature (-40~230℃), medium temperature (-40~450℃), high temperature (-40~550℃), low temperature (-40~-196℃) |

|||||||||||||||||

|

flange standard |

JB79,HG20592,GB,ANSI,JIS,DIN |

|||||||||||||||||

|

Adjustable ratio |

50:1 |

|||||||||||||||||

|

leak level |

Metal hard seal grade Ⅳ, PTFE soft seal grade Ⅵ |

|||||||||||||||||

Main technical parameters of HA multi-spring pneumatic diaphragm actuator

|

Model |

HA1D(R) |

HA2D(R) |

HA3D(R) |

HA4D(R) |

|

Effective area cm2 |

160 |

310 |

550 |

950 |

|

stroke mm |

14.3,25 |

14.3,25,38 |

14.3,25,38,40,50 |

14.3,25,38,40,50,60,75 |

|

Spring range Kpa |

20-100, 40-200, 80-240, 20-60, 60-100 |

|||

|

Air source pressure Mpa |

0.1-0.4 |

|||

|

Air supply connector |

RC1/4 |

|||

Pneumatic control valve Main parts material

|

Part Name |

Part material |

|

valve body, bonnet |

WCB,CF8(304),CF8M(316) |

|

valve core, valve stem, valve seat |

304, 316, 304 surfacing alloy, 316 surfacing alloy |

|

packing |

PTFE, flexible graphite |

|

sealing gasket |

Graphite Wound Gasket, Tooth Gasket |

|

Membrane cover |

A3 |

|

Diaphragm |

Ethylene propylene rubber sandwiched nylon fabric |

|

spring |

60Si2Mn |

|

Putting |

2Cr13 |

Pneumatic control valve performance index

|

project |

Index value |

project |

Index value |

||||

|

Basic Error% |

Without positioner |

±5.0 |

Start point end point deviation % |

air shut |

Without positioner |

start point |

±5.0 |

|

With positioner |

±1.0 |

end point |

±2.5 |

||||

|

Return difference % |

Without positioner |

≤3.0 |

With positioner |

start point |

±1.0 |

||

|

With positioner |

≤1.0 |

end point |

±1.0 |

||||

|

Dead zone |

Without positioner |

≤3.0 |

air open |

Without positioner |

start point |

±2.5 |

|

|

With positioner |

≤0.4 |

end point |

±5.0 |

||||

|

Rated stroke deviation% |

±2.5 |

With positioner |

start point |

±1.0 |

|||

|

end point |

±1.0 |

||||||

|

Allowable leakage L/h |

1×10-3 Valve rated capacity |

||||||

HTSW bellows regulating valve Allowable differential pressure MPa

|

switching method |

Executive agency |

Spring range Kpa |

Air source pressure Kpa |

positioner |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

|

air shut |

HA2D |

20-100 |

140 |

yes or no |

0.31 |

0.19 |

0.13 |

0.08 |

0.05 |

0.03 |

0.02 |

|

|

|

|

20-100 |

160 |

yes |

1.58 |

0.96 |

0.68 |

0.39 |

0.25 |

0.17 |

0.10 |

|

|

|

||

|

80-240 |

400 |

yes |

2.0 |

2.0 |

2.0 |

1.08 |

0.74 |

0.52 |

0.29 |

|

|

|

||

|

4.7 |

2.8 |

|||||||||||||

|

HA3D |

20-100 |

140 |

yes or no |

0.56 |

0.34 |

0.24 |

0.14 |

0.08 |

0.06 |

0.03 |

0.02 |

0.01 |

|

|

|

20-100 |

160 |

yes |

2.0 |

1.71 |

1.21 |

0.07 |

0.44 |

0.31 |

0.17 |

0.11 |

0.07 |

|

||

|

2.8 |

|

|||||||||||||

|

80-240 |

400 |

yes |

2.0 |

2.0 |

2.0 |

2.0 |

1.32 |

0.98 |

0.52 |

0.33 |

0.20 |

|

||

|

5.0 |

5.0 |

3.6 |

2.1 |

|

||||||||||

|

HA4D |

20-100 |

140 |

yes or no |

|

|

0.41 |

0.24 |

0.15 |

1.11 |

0.06 |

0.03 |

0.02 |

0.01 |

|

|

20-100 |

160 |

yes |

|

|

2.0 |

1.21 |

0.76 |

0.53 |

0.3 |

0.19 |

0.12 |

0.07 |

||

|

80-240 |

400 |

yes |

|

|

2.0 |

2.0 |

2.0 |

1.61 |

0.91 |

0.58 |

0.35 |

0.22 |

||

|

5.0 |

3.6 |

2.25 |

||||||||||||

|

air open |

HA2R |

20-100 |

140 |

yes or no |

0.31 |

.019 |

0.13 |

0.08 |

0.05 |

0.03 |

0.02 |

|

|

|

|

80-240 |

280 |

yes |

2.0 |

1.35 |

0.7 |

0.55 |

0.34 |

0.24 |

0.14 |

|

|

|

||

|

2.2 |

||||||||||||||

|

HA3R |

20-100 |

140 |

yes or no |

0.56 |

0.34 |

0.24 |

0.14 |

0.08 |

0.06 |

0.03 |

0.02 |

0.01 |

|

|

|

80-240 |

280 |

yes |

2.0 |

2.0 |

1.7 |

0.98 |

0.61 |

0.43 |

0.24 |

0.15 |

0.09 |

|

||

|

3.9 |

2.3 |

|||||||||||||

|

HA4R |

20-100 |

140 |

yes or no |

|

|

0.29 |

0.17 |

0.10 |

0.07 |

0.04 |

0.02 |

0.01 |

0.01 |

|

|

80-240 |

400 |

yes |

|

|

2.0 |

1.57 |

1.01 |

0.75 |

0.42 |

0.27 |

0.160 |

0.10 |

Reviews

There are no reviews yet.