1. Overview of electric flange butterfly valve:

D941X Electric Flange Soft Seal Butterfly Valve is suitable for water supply and drainage and gas pipelines with temperature ≤120℃ and nominal pressure ≤1.6MPa for food, medicine, chemical industry, petroleum, electric power, light textile, papermaking and other water supply and drainage and gas pipelines.

The electric flanged butterfly valve is composed of an electric actuator and a flanged inch butterfly valve, which can be divided into switch control and intelligent adjustment (4-20ma analog signal control) according to the working mode and conditions. The actuator works, the rotating system drives the disc on and off in the 0-90 range. The structural performance of the electric flanged butterfly valve is better than that of the wafer inch butterfly valve. It is recommended to use the electric flanged butterfly valve under the conditions of high pressure resistance and diameter exceeding DN600.

Features of Electric Flange Soft Seal Butterfly Valve-Overview Description-Working Principle-Standard Design Standards-Dimensions

|

Valve basic parameters |

|

|

product name: |

Electric Flange Soft Seal Butterfly Valve |

|

Product number: |

D941X |

|

Connection method: |

Flange connection |

|

Structural way: |

Midline type structure |

|

Drive mode: |

Electric |

|

Product caliber: |

DN50-DN1800 |

|

Nominal pressure: |

0.6-1.6MPA |

|

Valve body material: |

Carbon Steel, Ductile Iron |

2. Performance characteristics of electric flange butterfly valve:

(1). The characteristics of flange butterfly valve can realize remote control;

(2). The power supply is the driving energy of the electric butterfly valve, with a wide range of power sources and wide coverage, saving human resources and improving work efficiency;

(3). A series of electric actuator options provide convenient operation and meet various control requirements, signal feedback, flow adjustment, explosion-proof and other functions,

(4). Ultra-small, mechanical self-locking, different seals can be replaced to adapt to different operating conditions.

(5). It is easy to install and maintain anywhere.

(6). The seal can be replaced, and the reliability has zero leakage to the two-way seal.

(7). The sealing material has the characteristics of anti-aging, anti-corrosion and long life.

3. Product parameters Electric flange butterfly valve working principle:

The electric flange butterfly valve uses an electric actuator to input a standard signal of 0-10ma, and the motor unit drives the angular torque of the gear, turbine and worm to rotate the disc. When the valve is fully opened, the thickness of the disc is the resistance of the medium flowing through the valve body, so the pressure drop through the valve is very small, so the flow control characteristics are very good. Electric flanged butterfly valves are available in two sill styles: elastic sill and metal sill. Elastomeric sealing valve that can be sealed on the valve body or attached around the disc. Metal-sealed valves generally outlast elastomeric-sealed valves, but are difficult to seal completely. Metal seals can accommodate higher operating temperatures, while elastomeric seals also suffer from temperature limitations. If flow control requires an electric flanged butterfly valve, the main thing is to choose the correct size and type of valve.

4. electric flange soft sealing butterfly valve executive standard

Design standard: GB/T12238-1989

Flange connection size: GB/T9113.1-2000; GB/T9115.1-2000;

Structure length: GB/12221-1989

Pressure test: GB/T13927-1992; JB/T9092-1999

5. Main technical parameters of electric butterfly valve

|

Nominal diameter |

DN(mm) |

50~2000 |

||

|

Nominal pressure |

PN(MPa) |

0.6 |

1.0 |

1.6 |

|

Test pressure Ps (MPa) |

Strength test |

0.9 |

1.5 |

2.4 |

|

sealing test |

0.66 |

1.1 |

1.76 |

|

|

Air tightness test |

0.6 |

0.6 |

0.6 |

|

|

Applicable media |

Air, water, sewage, steam, gas, oil, etc. |

|||

|

drive mode |

Manual, worm and worm gear drive, pneumatic drive, electric drive. |

|||

6. The material of the main parts of the flange soft sealing butterfly valve

|

Part Name |

Material |

|

valve body |

Ductile iron+NBR/EPDM |

|

Butterfly board |

Ductile cast steel, cast steel, stainless steel and special materials |

|

sealing ring |

Ductile cast steel, cast steel, alloy steel, stainless steel |

|

valve stem |

2Cr13, stainless steel |

|

packing |

O-Ring, Flexible Graphite |

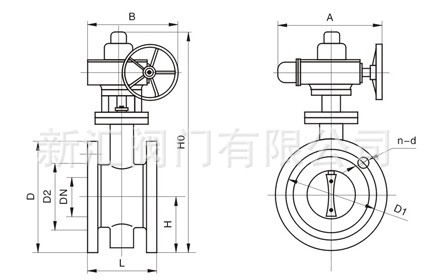

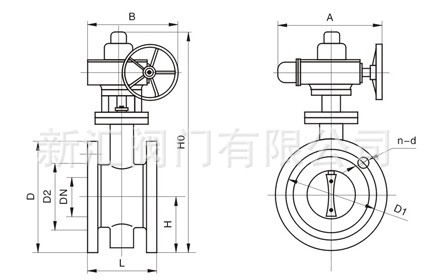

7. Electric main connection and external dimensions

|

Nominal diameter |

structure

length |

External Dimensions (Reference Value) |

Connection size (standard value) |

refer to

weight |

|||||||

|

0.6MPa |

|||||||||||

|

mm |

inch |

L |

H |

H0 |

A |

B |

D |

D1 |

D2 |

n-d |

|

|

50 |

2 |

108 |

63 |

306 |

180 |

200 |

140 |

110 |

88 |

4-14 |

13 |

|

65 |

21/2 |

112 |

70 |

321 |

180 |

200 |

160 |

130 |

108 |

4-14 |

14 |

|

80 |

3 |

114 |

83 |

346 |

180 |

200 |

190 |

150 |

124 |

4-18 |

15.5 |

|

100 |

4 |

127 |

105 |

387 |

180 |

200 |

210 |

170 |

144 |

4-18 |

19.5 |

|

125 |

5 |

140 |

115 |

411 |

180 |

200 |

240 |

200 |

174 |

8-18 |

25.5 |

|

150 |

6 |

140 |

137 |

447 |

270 |

280 |

265 |

225 |

199 |

8-18 |

28.5 |

|

200 |

8 |

152 |

164 |

572 |

270 |

280 |

320 |

280 |

254 |

8-18 |

48 |

|

250 |

10 |

250 |

206 |

646 |

270 |

280 |

375 |

335 |

309 |

12-18 |

69 |

|

300 |

12 |

270 |

230 |

738 |

380 |

420 |

440 |

395 |

363 |

12-22 |

91 |

|

350 |

14 |

290 |

248 |

761 |

380 |

420 |

490 |

445 |

413 |

12-22 |

110 |

|

400 |

16 |

310 |

289 |

877 |

450 |

470 |

540 |

495 |

463 |

16-22 |

140 |

|

450 |

18 |

330 |

320 |

938 |

480 |

490 |

595 |

550 |

518 |

16-22 |

180 |

|

500 |

20 |

350 |

343 |

993 |

480 |

490 |

645 |

600 |

568 |

20-22 |

215 |

|

600 |

24 |

390 |

413 |

1131 |

480 |

490 |

755 |

705 |

667 |

20-26 |

290 |

|

700 |

28 |

430 |

478 |

1476 |

640 |

660 |

860 |

810 |

772 |

24-26 |

560 |

|

800 |

32 |

470 |

525 |

1533 |

640 |

660 |

975 |

920 |

878 |

24-30 |

910 |

Reviews

There are no reviews yet.